News & press

Fashion for Good Selects Twelve Innovators for 2023 Innovation Programme

In conversation with Smartex: Explore Smartex’s AI-driven solutions transforming quality control and reducing waste

Fashion for Good and Textile Exchange Team Up to Trace Textile Waste

In Conversation with Living Ink: Turning Biomass Waste Into Value

In Conversation with NTX: Pioneering Digital Dyeing

In Conversation with Alchemie Technology: Transforming Dry Processing for Textile Dyeing and Finishing

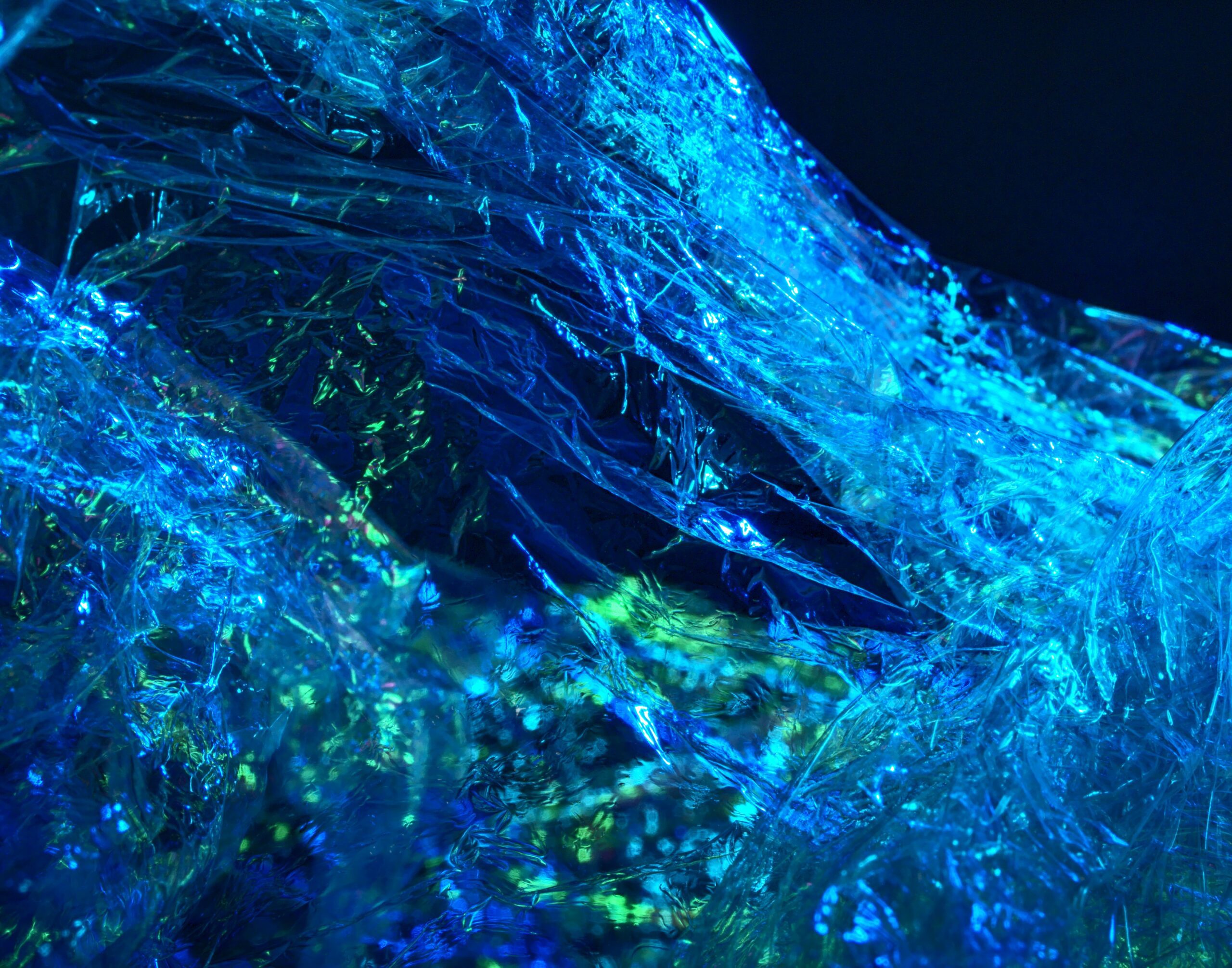

The Colourful Challenge of Textiles

In Conversation with imogo: Reimagining Spray Dyeing

In Conversation with Colorifix: Revolutionising Textile Dyeing with Biotechnology

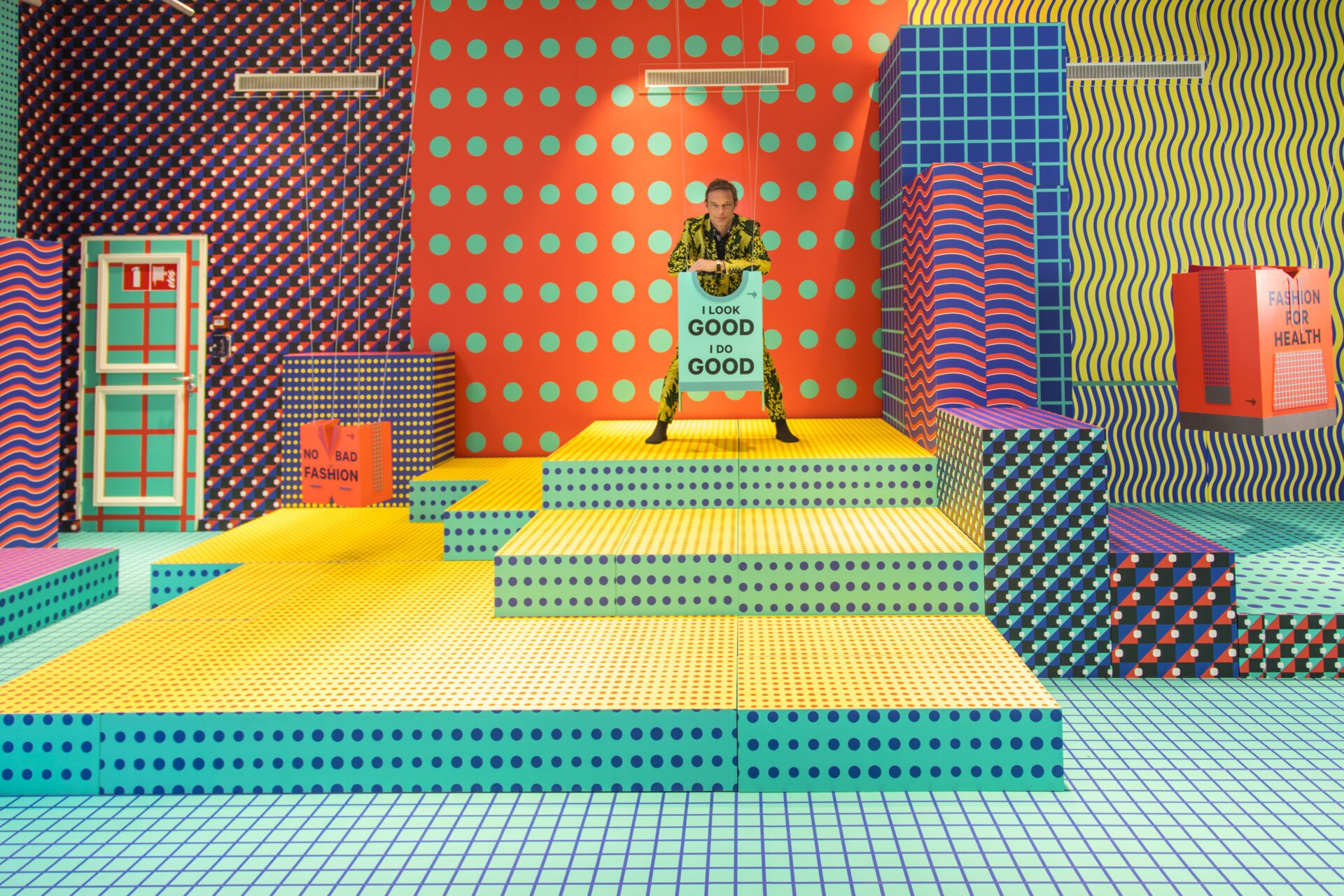

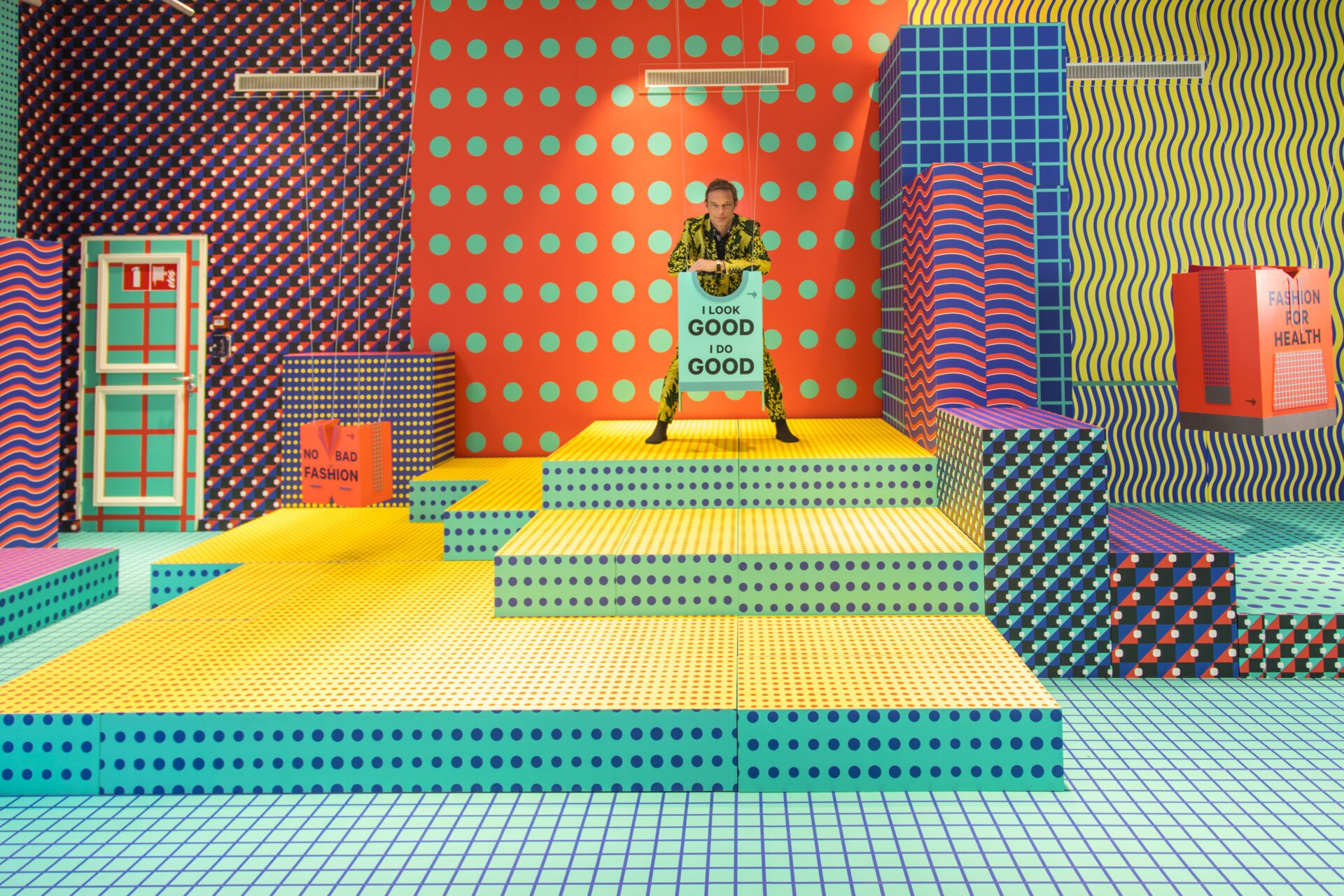

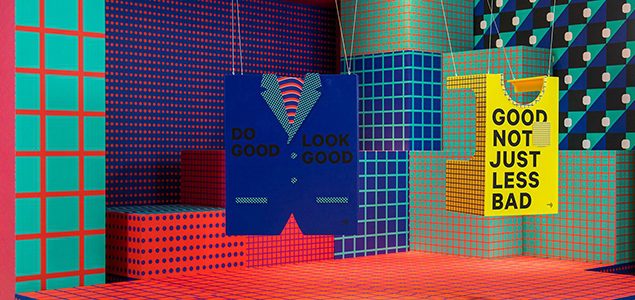

Fashion for Good Museum shares its legacy and embarks on a new phase

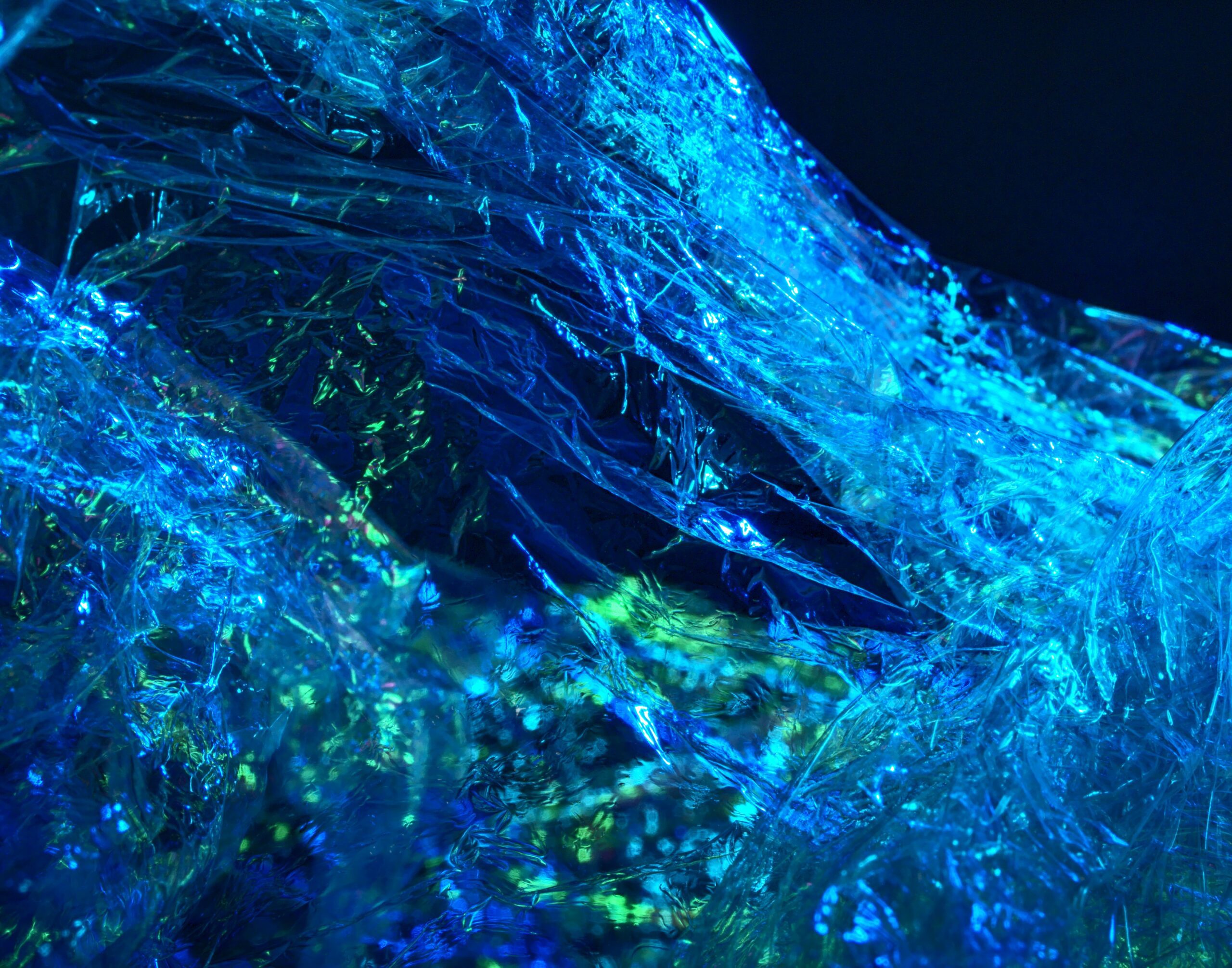

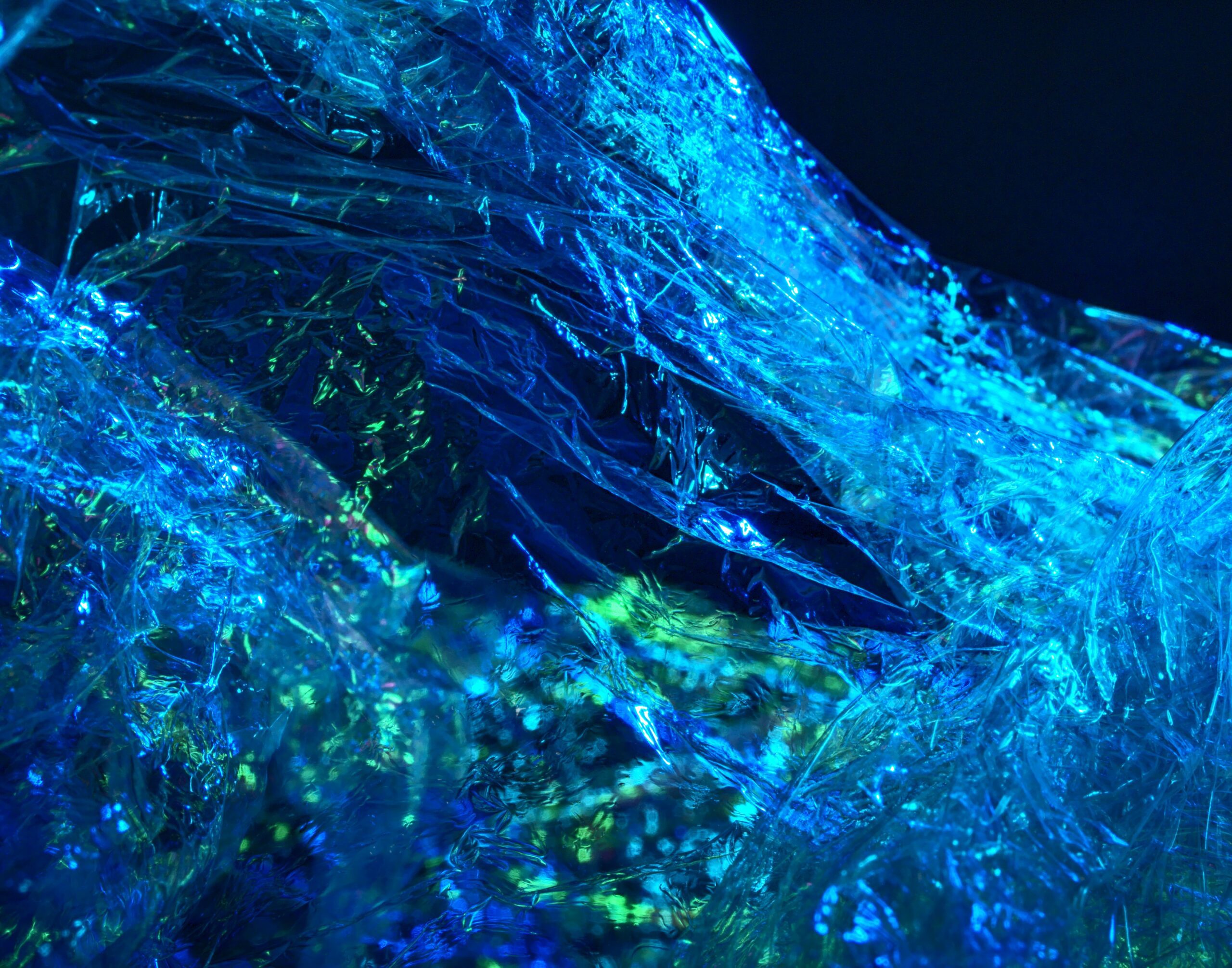

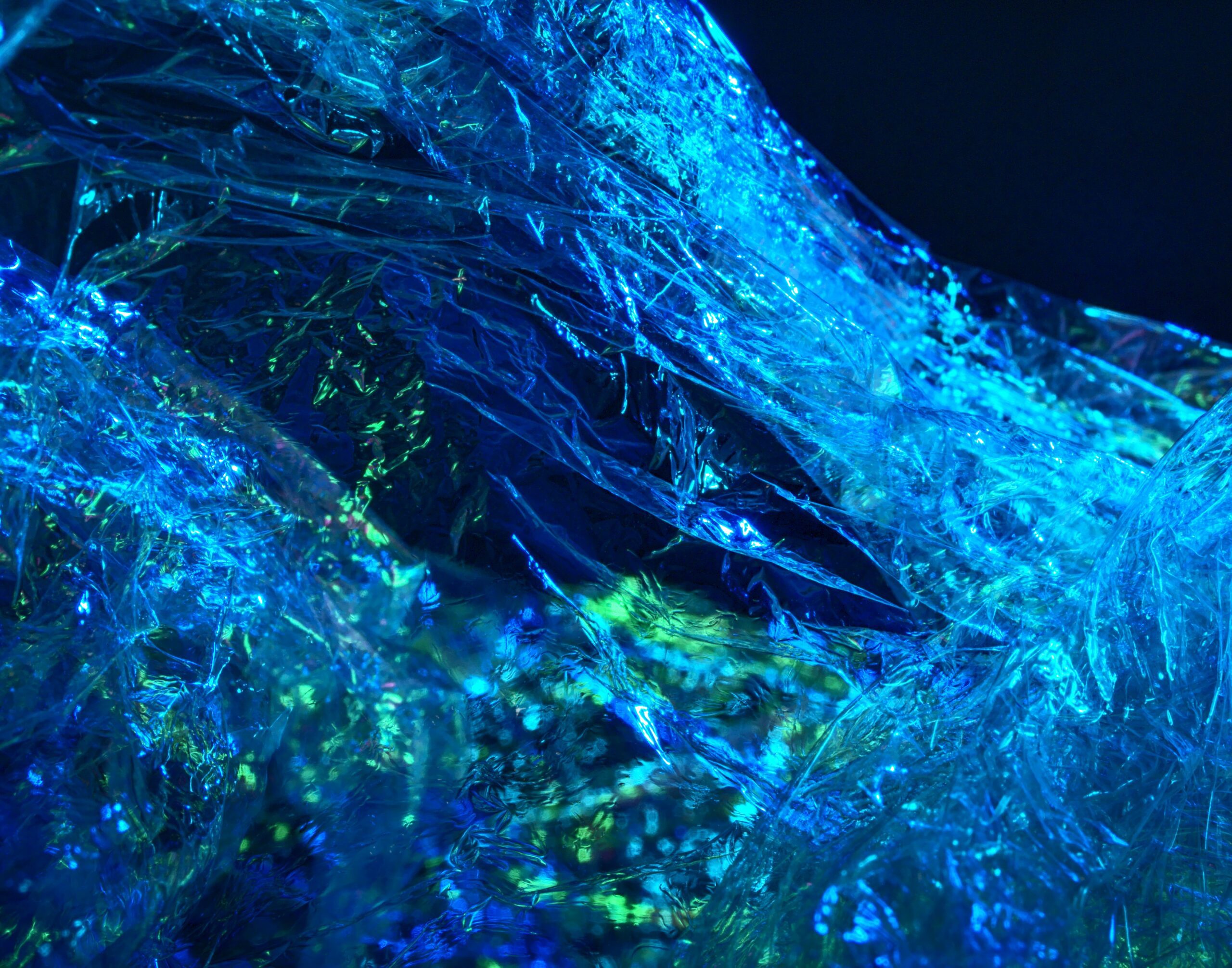

In Conversation with Ambercycle: Introducing Molecular Regeneration Technology

In Conversation with CuRe Technology: How Can We Create a Fully Circular Polyester Chain?

Meet the Innovator: CuRe Technology

Can we recycle polyester?

Fashion for Good Welcomes Ten New Innovators to Its 2024 Innovation Programme

5 FAQS About ‘Leather’ Alternatives

How Can We Make ‘Leather’ Alternatives With Green Waste?

From Fallen Leaves to ‘Leather’ Alternatives | Biophilica

What are biomaterials in fashion?

VAT Tax Impact on Resale in the UK

Sorting for Circularity Europe Expands to Address Rewearable Textile Crisis

Fashion for Good Unveils Five-year Strategy Shifting to Scale Innovation in Fashion

Sorting for Circularity India Toolkit Launched: Pioneering Partnership Sets India on Path to Next-Gen Textiles Leadeship

In Conversation with Renewcell: The Innovator Turning Worn-out Clothes into Next-gen Materials

Open Letter to the Fashion Industry

Meet the Innovator: Renewcell

In Conversation with Circ: The Innovator Turning Textile Waste into New Materials

Fashion for Good and Spring Lane Capital Report Defines How Project Finance Can Bridge the Innovation Commercialisation Gap

Meet the Innovator: Circ

What is chemical recycling?

In Conversation with Trove: The Innovator Powering the Resale Ecosystem For Brands

Meet the Innovator: Trove

What are circular business models?

What is circularity?

Meet the Innovator: Oritain

What is transparency?

In Conversation with TextileGenesis: The Innovator Creating Transparent Supply Chains

Fashion for Good Partners adidas, Inditex, Target & Zalando Join Forces with FastFeetGrinded for Circular Footwear

What are microfibres and microplastics in fashion?

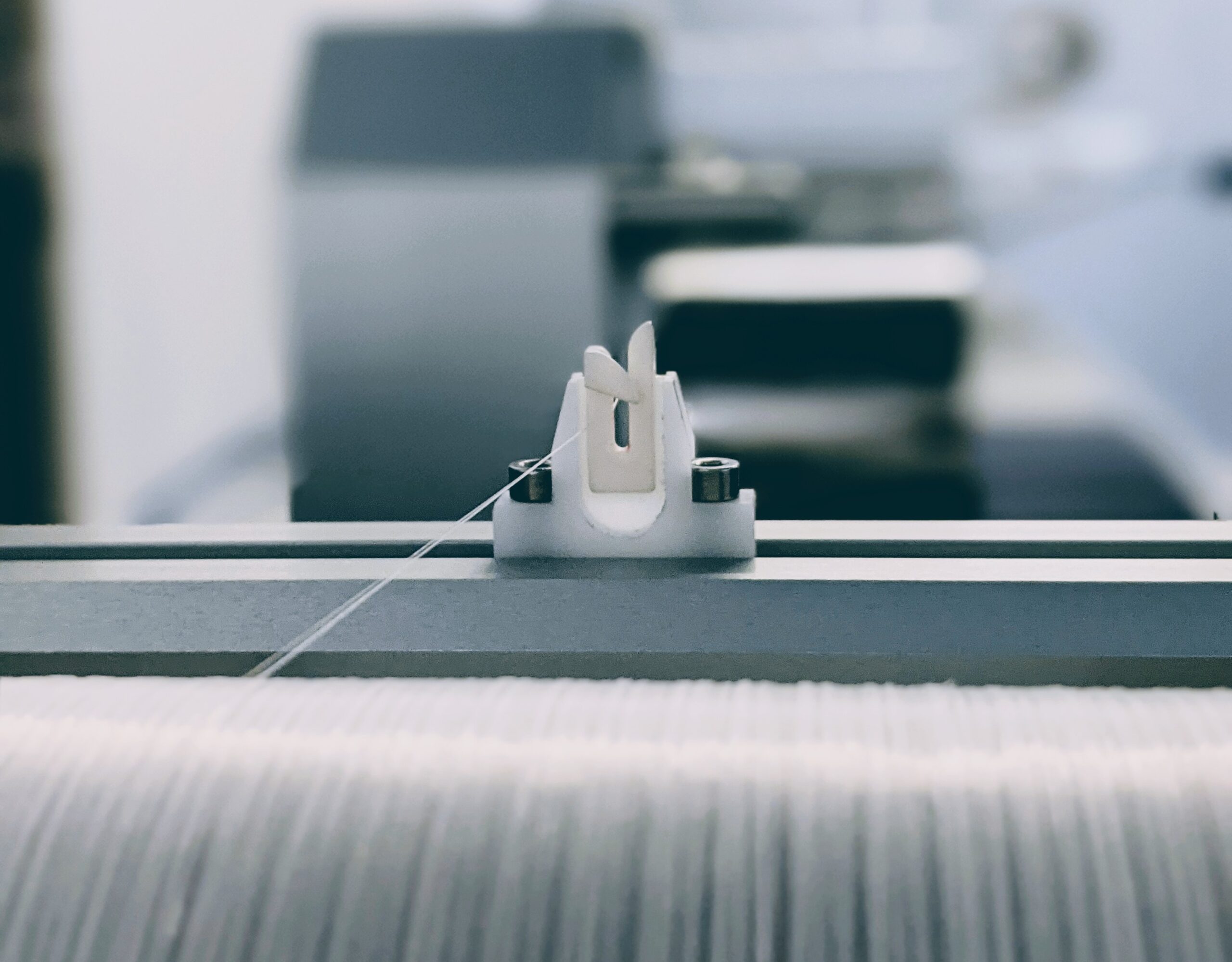

Textile Processing - How disruptive innovation can pave the way to a sustainable fashion supply chain | Part II

What is traceability?

Textile Processing - How disruptive innovation can pave the way to a sustainable fashion supply chain | Part I

What is mycelium?

Driving Circular Innovation Forward: Fashion for Good Welcomes New Partners to its Sorting for Circularity USA Project

Meet the Innovator: TextileGenesis™

Meet the Innovator: Ecovative

In Conversation with Ecovative: The Innovator Unlocking the Power of Mycelium

Meet the Innovator: Infinited Fiber Company

What is textile processing? Understanding the fashion supply chain and its environmental impact

Fashion for Good's Newest Project with BESTSELLER, Inditex, and Reformation Prototypes Kintra Fibers' Biobased Polyester

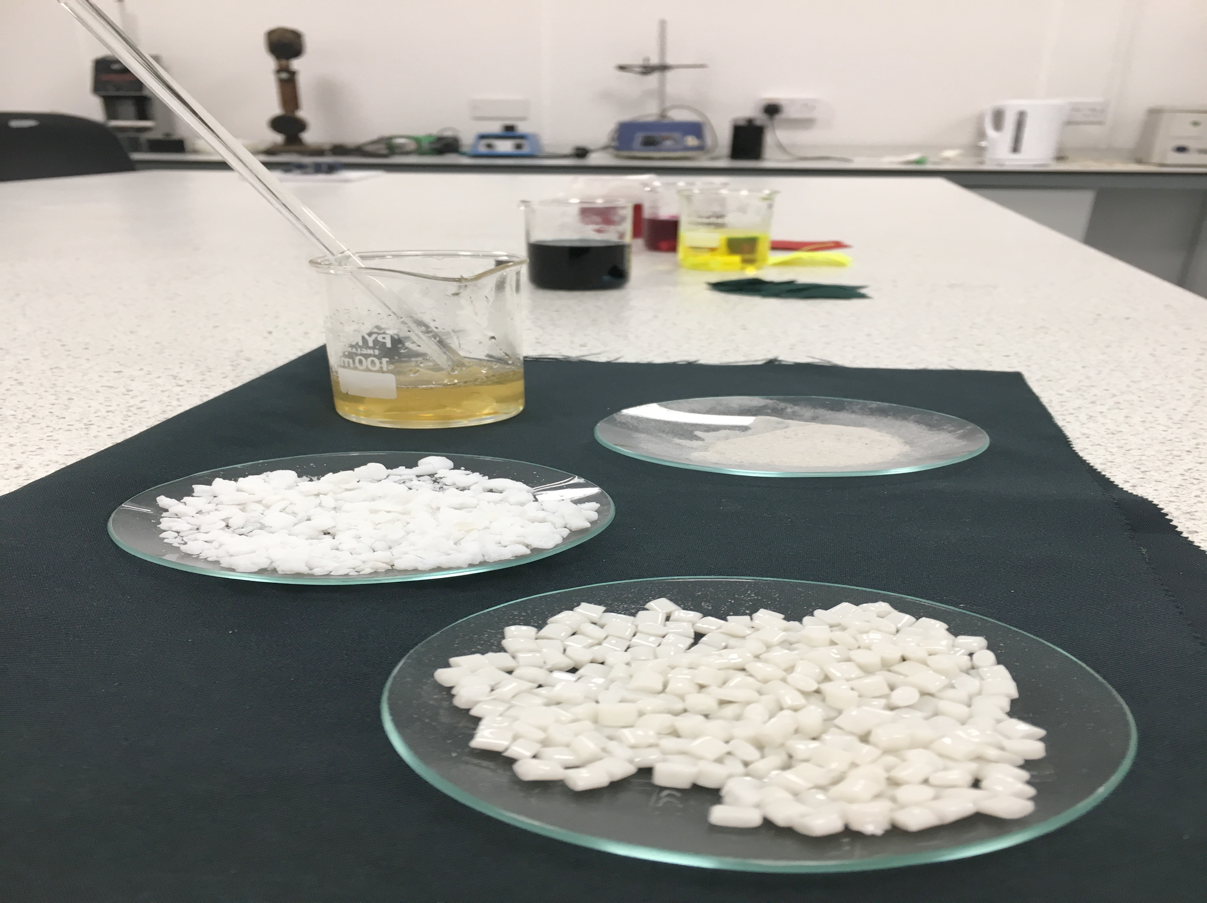

Fashion for Good Develops a Sustainable Dyestuff Library

Fashion for Good Selects Twelve Innovators for 2023 Innovation Programme

Fashion for Good Sorting for Circularity Advances into the US Market

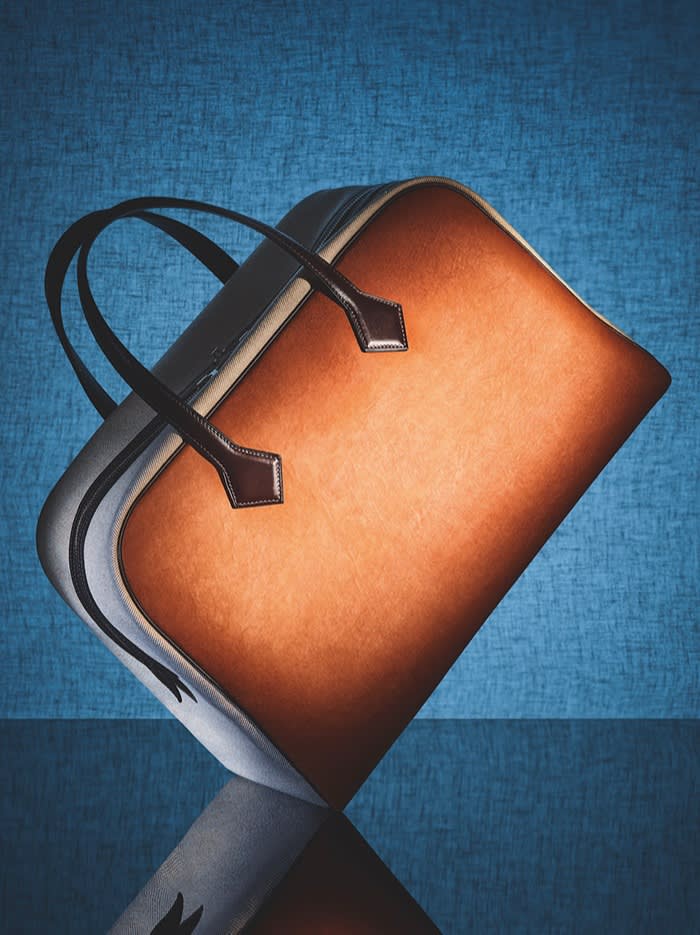

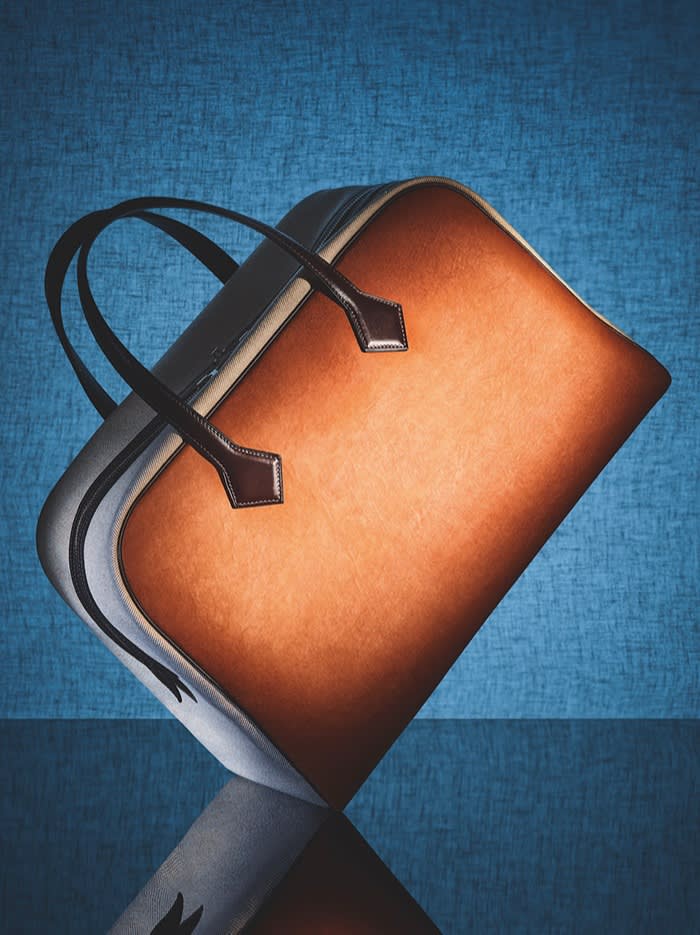

BESTSELLER Collaborates With Biophilica In Fashion for Good Pilot To Test The Compostable Leather Alternative Treekind®

Fashion for Good Launches the Home-Compostable Polybag Project

Good Fashion Fund's First Investment Demonstrates Impact

Innovation Challenge: Call for Innovation in the Asian Textile Industry

New Cotton Project Launches Exhibit at the Fashion for Good Museum

Creating a Circular System to Accelerate Textile Recycling

Sorting For Circularity Europe: Project findings highlight immense opportunity to accelerate textile recycling

Jill Beraud Named Chair of the Fashion for Good BV Board

Wealth in Waste: India's Potential to Lead Circular Textile Sourcing

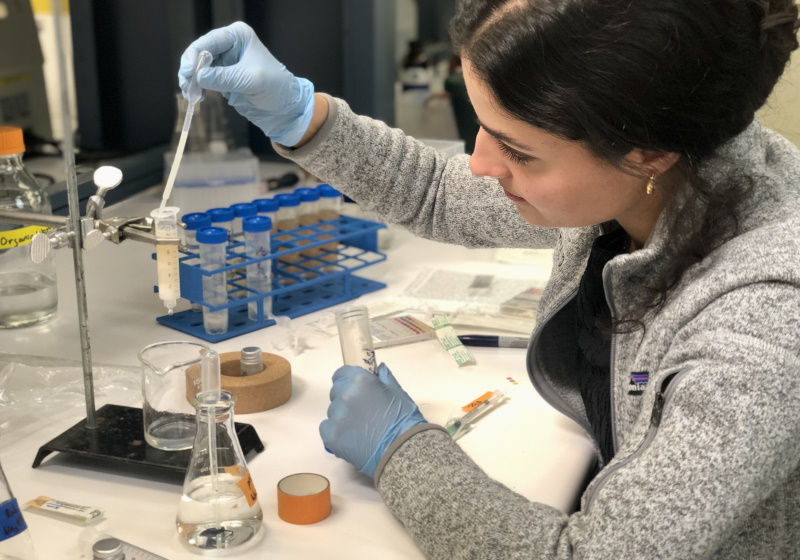

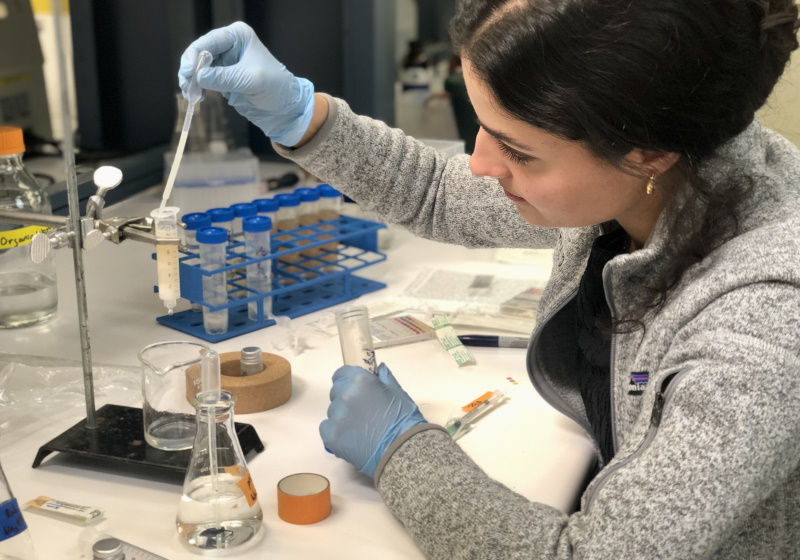

Assessing Tracer Technologies to Boost Traceability

Seven Innovators Join Fashion for Good's 2022 Asia Innovation Programme

Fashion for Good Selects Eight Innovators for 2022 Global Innovation Programme

The Next Generation of Materials... From Waste

New Partners Join the Sorting for Circularity Project

From Waste to Black Pigment

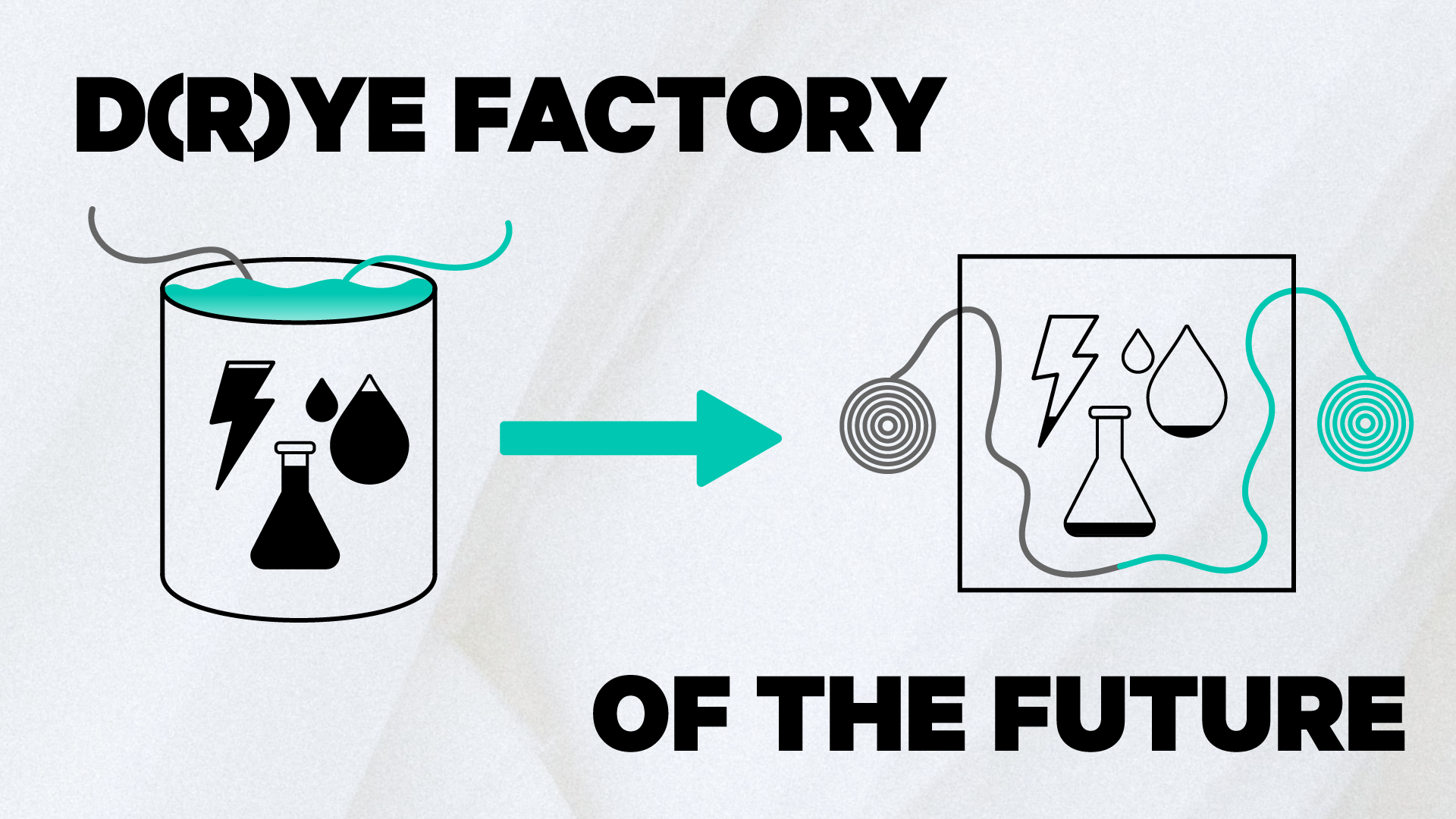

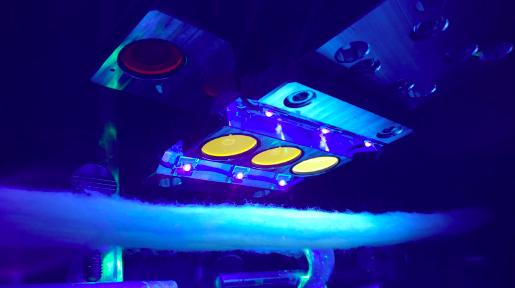

Fashion for Good Launches D(R)YE Factory of the Future Project

Ecovative Launches Fashion for Good Cooperative with BESTSELLER and PVH Corp.

Plant-Based Indigo Presents a Solution for the Future of Denim Dyeing

Full Circle Textiles Project Focuses on Scaling Polyester Recycling

Fashion for Good Asia Builds Momentum With New Partner, Consortium and Innovations

Fashion for Good Launches The Sorting for Circularity India Project

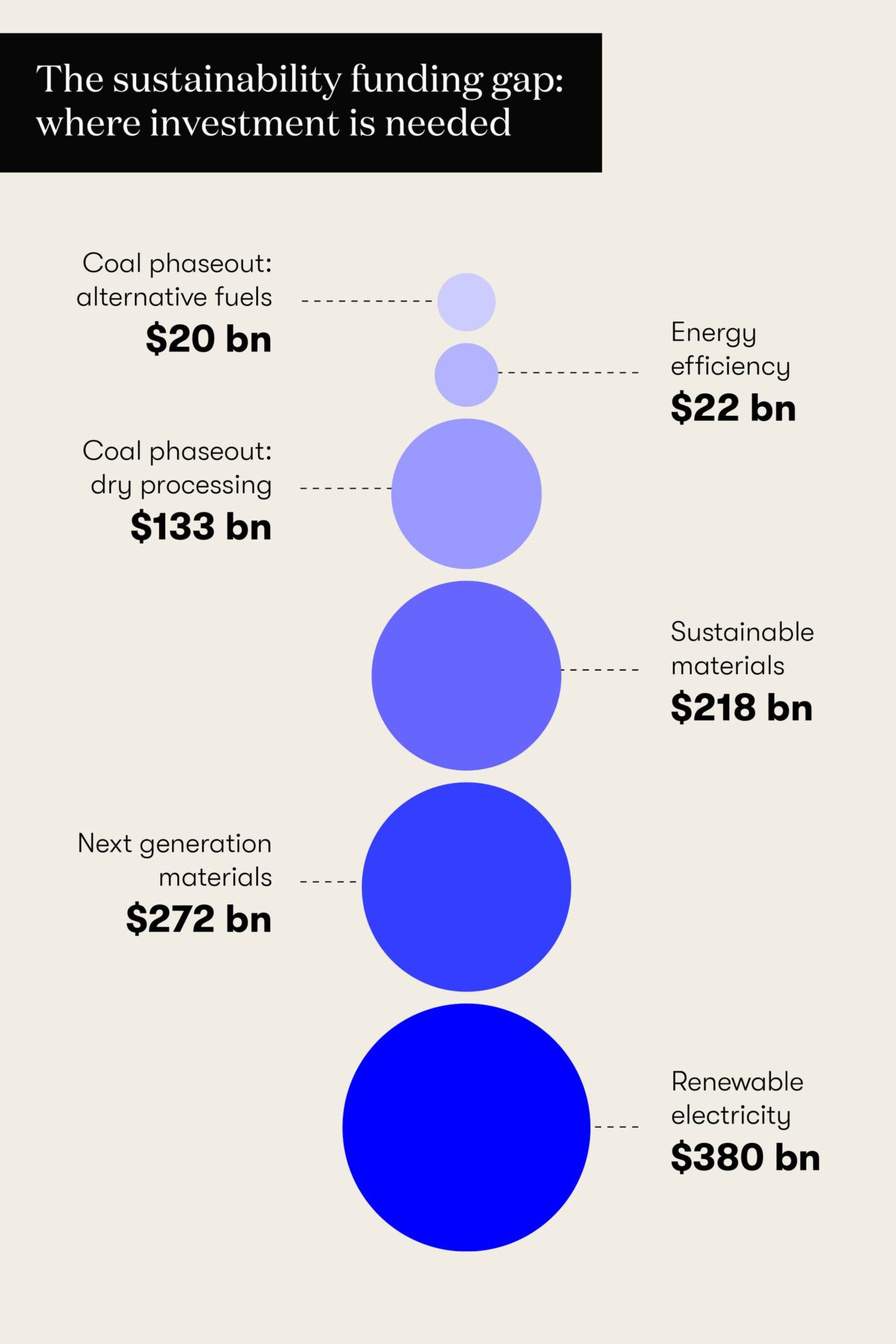

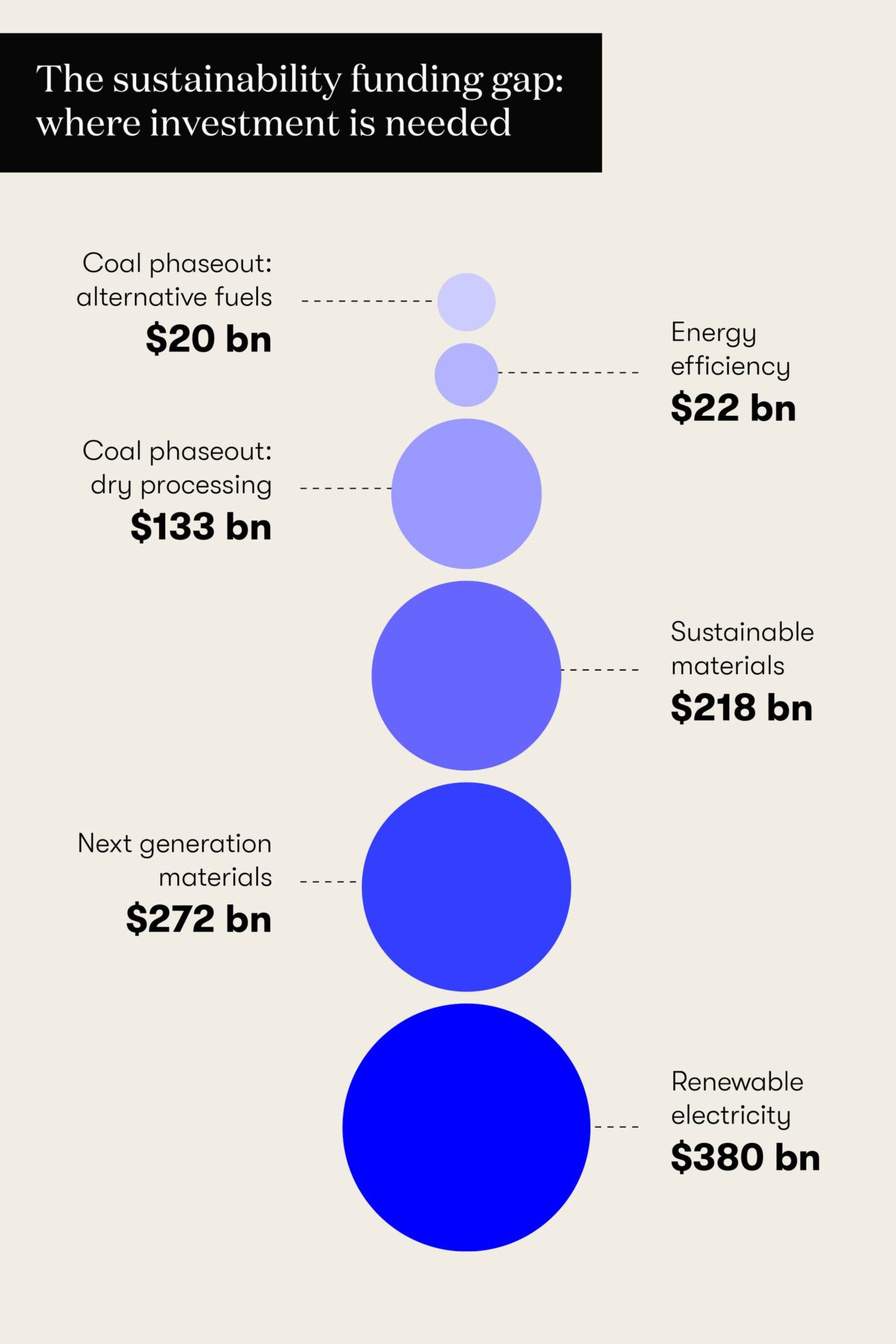

Unlocking the Trillion-Dollar Fashion Decarbonisation Opportunity

Fashion for Good Welcomes GORE-TEX Brand

Good Fashion Fund Signs Contract With First Project

From Fibre To Finish To Scale: Tracing Viscose And Beyond

Fashion for Good Launches The Renewable Carbon Textiles Project

Sorting For Circularity; Fashion for Good Launches New Project To Drive Textile Recycling

The Path To Scaling Reusable Packaging In E-commerce

Fashion for Good South Asia Breaks New Territory With Third Batch Of Innovators

Levi Strauss & Co. Joins Fashion for Good

14 Trailblazing Innovators Make Fashion for Good's 8th Batch In Their Global Programme

Fashion for Good Consortium Pilots Resource Efficient Cotton Farming

Understanding 'Bio' Material Innovations: A Primer for the Fashion Industry

Fashion for Good Celebrates Success of First Year in South Asia

From Fibre to Finish: Tracing Sustainable Viscose

Going Beyond Cotton – New Project Harnesses Collaboration & Cutting-edge Technology to Create Circular Fashion

Report Launch: Fashion Innovation Landscape in India

Piloting a Circularity Solution in E-commerce

A New Frontier in Chemical Recycling

Leading NGOs unite as the Fashion Conveners to Accelerate Sustainable Transformation of the Apparel and Accessory Industry

Piloting a Ground-Breaking Solution to Clean Wastewater

9 New Innovators Selected Virtually For Second Batch of Fashion for Good's South Asia Innovation Programme

Good Fashion Fund Welcomes Rabobank

Fashion for Good Presents Findings of Survey Assessing the Impact of Covid-19 on Fashion Startups

In response to COVID-19: a message to our community

Fashion for Good Selects Innovators During First Virtual Selection Day

Fashion for Good Selects First Start-ups for South Asia Innovation Programme

Fashion for Good & BCG launch New Report - Financing the Transformation in Fashion

Fashion for Good Launches a Pilot to Produce a Circular Polybag

Fashion for Good Hosts First Innovation Day in South Asia with Colombo Innovation Tower

Fashion for Good Expands Activities in South Asia, Partners with Welspun

Successfully Tracing Organic Cotton with Innovative Technologies

Meet the 12 Start-ups Driving Fashion's Innovation Revolution

Good Fashion Fund Launches to Invest in Supply Chain Innovation

Fashion for Good Launches Programme Expansion In Asia

Fashion For Good Presents The Future of Fashion

Driving Circular Business Models in Fashion

Arvind joins Fashion for Good

Circle Economy and Fashion for Good join forces to enable circular business models

Scaling Programme Fashion For Good Expands

Fifth Batch Of Innovators Start At Fashion for Good

Norrøna joins Fashion for Good

Fashion for Good and Bestseller Join Forces

Fashion for Good launches partnership with Otto Group, OTTO and bonprix

5 Innovators Join Fashion for Good's Scaling Programme

Stella McCartney Joins Fashion for Good

Fashion for Good and ZDHC call for innovators

Rethinking the business of fashion with 12 new start-ups

Fashion for Good launches ground-breaking Cradle to Cradle Certified Denim and Materials toolkit

Spinnova joins Fashion for Good’s Scaling Programme

Fashion for Good and PVH Corp. Launch Partnership

Fashion for Good celebrates progress with Innovation Fest

Fashion for Good welcomes three innovators to Scaling Programme

15 innovations set to change the fashion industry?

Fashion for Good-Plug and Play accelerator announces third batch of start-ups

Fashion for Good and adidas partner to accelerate and scale sustainable innovation in the apparel industry

Fashion for Good partners with Zalando to accelerate and scale sustainable innovation in the fashion industry

Fashion for Good closes out first year with cross-industry convening to accelerate and scale daring innovation in fashion

Fashion for Good and ColorZen collaborate through Scaling Programme

Fashion for Good invites The Infinited Fiber Company to its Scaling Programme

Fashion for Good invites Worn Again to its Scaling Programme

Fashion for Good invites SoftWear Automation to its Scaling Programme

First edition of start-ups graduate from Accelerator Programme and second batch unveiled

Fashion for Good invites Tamicare Ltd to its Scaling Programme

Katrin Ley named Fashion for Good Managing Director

The Galeries Lafayette group joins Plug and Play - Fashion for Good accelerator

Innovation, collaboration and community

Meet the startups from our early-stage accelerator program

C&A calls upon fashion industry to join the journey towards circular fashion

Innovation, collaboration and community shine at Fashion for Good's launch

First start-ups to join accelerator programme

What are the most promising new innovations?

Fashion for Good brings the Good to Fashion.

Startups key to change in the fashion industry?

Supply chain innovation is sorely needed. Who’s going to fund it?

Fashion brands and suppliers are facing more pressure and increased regulations on how products are made and dealt with at end of life, all while dealing with rising costs. The funding required to innovate and upgrade remains elusive.

How Deep Tech Can Drive Sustainability and Profitability in Manufacturing

Companies are facing more pressure to become more sustainable while remaining profitable — and deep tech can help.

Setting up a sustainable fashion company? It's really possible if you keep these choices in mind.

Despite a brilliant idea, innovative design or strong name, sustainably running a company as a starting entrepreneur can be difficult. [DUTCH ARTICLE]

Can the fashion industry move from recycled bottles to reused threads?

There’s probably enough clothing on the planet that there’s no need to spin another new fibre. In the United States and European Union almost 22 million tonnes of textiles are thrown out every year. The waste is found everywhere from the ocean to the Atacama Desert.

The circular fashion challenge: Can AI help to close the loop?

As the concept of circular fashion has gained traction, researchers and entrepreneurs are developing tools they hope brands will implement to finally close the loop. One of the latest is new AI sorting technology developed by California-based company Refiberd.

What If Polyester Isn’t So Bad After All?

The most-used material in clothing may also be the ultimate recyclable fibre.

Startups Are Vying to Fix One of Fashion’s Fossil-Fueled Secrets

Transferring dye to fabric is incredibly carbon-intensive. Newer sustainable techniques, including coloring with carbon dioxide, may help.

How Can Companies Recycle Clothes Back Into Clothes?

Polyester is in almost all of your clothing, and it’s almost impossible to recycle. Some innovators are looking beyond turning plastic bottles into fabric.

The Fashion Charter is on track to miss its key goal. What now?

In a recent report, the UN Fashion Charter said there’s still a long way to go to meet its net-zero emissions goal, and signatories are dropping. It’s raised questions about impact and accountability.

Dress made of orange peel at the GROW exhibition in Budapest

The GROW pop-up exhibition of the Fashion for Good Museum is open in Hungary until 25 March. The interactive exhibition showcases clothes and accessories made from sustainable bio-materials such as banana fibre, orange and coconut shells, and is located at the Budapest Metropolitan University. [HUNGARIAN ARTICLE]

Smart Creation, the podcast. Episode 54

In this new episode of the podcast Smart Creation, Kathleen Rademan, Director of the Innovation Platform at Fashion for Good tells us how the platform works, how it is financed, its innovative projects and the particularity of their museum.

'Truly sustainable?' Vogue's guide to sustainable fashion

What is sustainability? How is it linked to the fashion industry? And what are the essential components when we define sustainable fashion? [DUTCH ARTICLE]

Green is the new black as fashion sector fast-forwards on sustainability trend

Fashion companies to look at making business models more circular in a bid to reduce supply chain risks.

Can textile innovation lead the fashion industry towards a sustainable future?

Can recycled and bio-based solutions accelerate the transformation in an industry that is circular when it comes to textile production? Fashion for Good helps investigating on how sustainable the industry can become in the short term.

Why fabric fraud is so easy to hide

How can we tell if the clothes in our wardrobes really are what they claim to be? Fashion for Good mentions the insights and issues of international fabrics’ certifications along the supply chains.

Fashion for Good launches the home-compostable polybag project

Fashion for Good launches the Home-Compostable Polybag Project, a pilot to test alternatives to conventional single-use polybags,

The vegan leather made from India’s waste flowers

Materials like 100% biodegradable Fleather from Phool, which was part of Fashion For Good’s innovation programme in 2020, stand out as a unique category.

Award Shortlists 2022

Fashion for Good was selected in three categories of the Excellence Category shortlists for the 2022 Awards organised by Just Style

Will We Ever Be Able to Recycle Our Clothes Like an Aluminum Can?

Fashion for Good innovator Renewcell’s new factory is one of the first steps toward a system that turns old clothes into new high-quality clothes made entirely with recycled fabric, addressing the mountains of textile waste accumulating worldwide.

The winners of Bazaar's Women of the Year Awards have been nominated

With pioneering ideas, Katrin Ley, winner Business category, wants to make the fashion industry more sustainable with her innovation platform and museum Fashion for Good and contribute to a better world. [DUTCH ARTICLE]

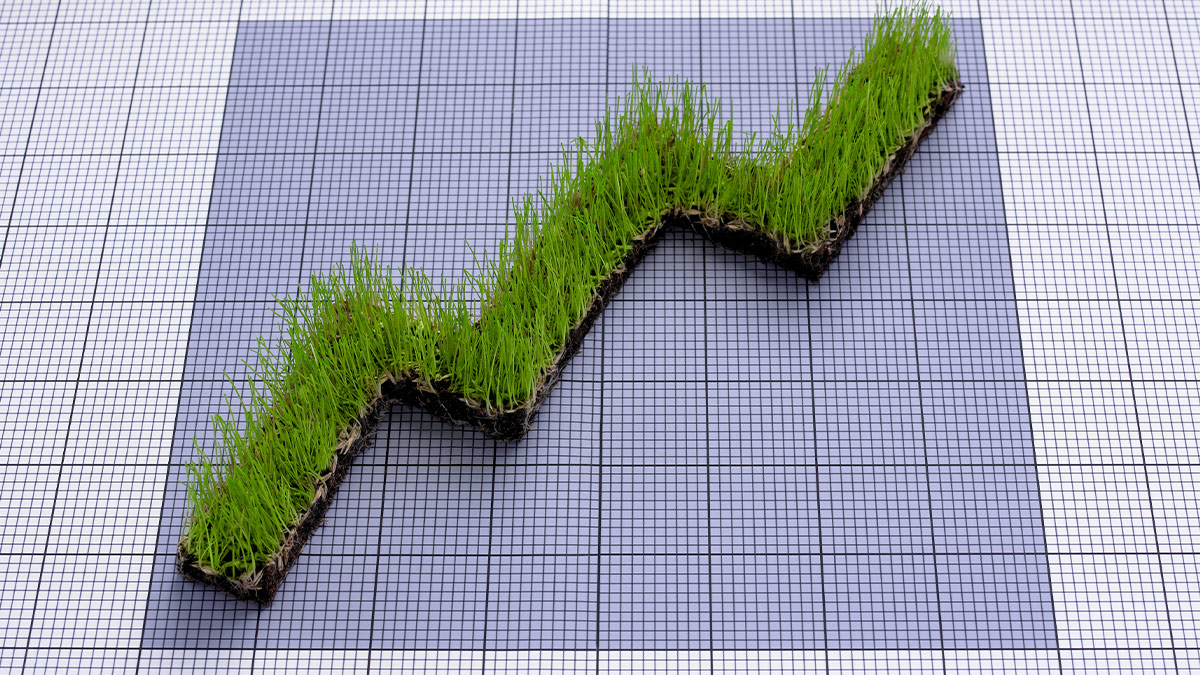

Recycling of textile waste in Europe could generate €74m per year, report

The Sorting for Circularity Europe Project highlights the significant opportunity for circularity, with only 2% of post-consumer textiles diverted to fibre-to-fibre recycling today.

Increased investment key to accelerating Europe’s textile recycling

As fibre-to-fibre textile recycling commitments increase across Europe, as well as the amount of textile waste collected, the infrastructure required to drive the move towards circular systems requires significant investment to scale.

Travel Through 50 Years of a Pair of Levi 501’s in Latest Buy Better, Wear Longer Initiative

Levi’s launched the next iteration of its “Buy Better, Wear Longer” campaign. The project is built on the brand’s long-term commitment to prolonging the lifespan of its products.

BioMaterials: resource of sustainable fashion

With an average growth between 15% and 20%, the circular fashion industry could reach 75 billion dollars in 2025. As a result, the EU funded the AllThing.BioPRO project to help consumers make more informed choices in bioeconomy.[ITALIAN ARTICLE]

With its soluble sewing thread, Resortecs facilitates the management of unsold garments

For a long time, the fashion industry has been caught up by its excesses such as overproduction. It is with the aim of giving new life to fabrics that the start-up developed two innovations, which, when combined, allow clothes to be easily “unsewn” and thus facilitate fabric recovery. [FRENCH ARTICLE]

Study Explores India’s Potential to Lead Circular Textile Sorting

India has the potential to secure a role as the leading circular textile sourcing region, according to a new first-of-its-kind study that claims to be the most comprehensive analysis of the Indian textile waste landscape.

Georgia Parker: "The Elephant in the Room Continues to be Overproduction"

A Innovation Platform Director at Fashion for Good explains that the pandemic highlighted the challenges that the sector must face when the supply chain is blocked and that, to face this, it is necessary to “implement innovative solutions”. [SPANISH ARTICLE]

Meet the Innovators Turning CO2 into Textiles

Chicago-based LanzaTech made headlines last year by working with Zara and Lululemon to make garments from captured steel mill emissions. Now Rubi Laboratories from San Francisco, recently raised US$4.5 million in a successful seed funding round to develop its method of producing cellulose from CO2.

Circular Startup Circ Raises Thirty Million Dollars from Inditex

Circular fashion company Circ has secured an investment of thirty million dollars, equivalent to thirty million euros. Several large corporations participated in the investment round, including the fashion group Inditex, according to a press release from Circ. [DUTCH ARTICLE]

The Latest Swimwear Takes Back to the 90s, Even the Thong Is Making A Comeback. But Then Made of Ocean Plastic

Swimwear is becoming a lot more sustainable thanks to Econyl, nylon made mainly from old fishing nets. “I immediately thought it was such a good story.” [DUTCH ARTICLE]

Key takeaways from the Global Fashion Summit: More diversity, more collaboration

Fashion leaders gathered in Copenhagen for the annual Global Fashion Summit. Circularity, carbon, community and pre-competitive collaboration, the four C’s of sustainability, dominated this year’s Global Fashion Summit in Copenhagen. The resounding message? Urgently needed progress is reliant on the industry working together to achieve it.

Fashion Brands, Ready To Accelerate Your Sustainable Transformation with Digital Traceability?

TrusTrace, a market-leading platform for supply chain transparency and product traceability within the fashion and retail industries, has joined forces with Fashion Revolution and Fashion for Good to accelerate sustainable transformation in the fashion industry with the help of a one-stop guide.

Bags and Shoes Made From Mushrooms: The Future?

Mycelium-fabrics with muschroom, offer an alternative for leather, hoping to make big fashion brands such as Stella McCartney and Adidas more sustainable. The production takes place in a nursery in the Gelderse Hedel. [DUTCH ARTICLE]

Fashion for Good Welcomes Asian Innovators

Sustainability initiative Fashion for Good has announced the seven innovators to take part in this year’s Asia Innovation Programme. Those selected – Picvisa, Gaiacel, An Herbals, Fermentech Labs, Sodhani Biotech, Vaayu and UKHI Hemp Foundation – are said to offer solutions which focus on raw materials, processing, and end-of-use.

Pangaia, Vivobarefoot, Ecovative to Research Mycelium in Fashion

The collective mycelium research pairs Vivobarefoot and Pangaia with Ecovative’s team of mycologists, engineers and designers, to develop a line of fungus-based, petroleum-free foams and hides for their products. It also sees the three join the Fashion for Good Cooperative.

Are These the New Heroes of Fashion?

At the heart of this growing revolution sits Fashion for Good (FFG), a global initiative that is catalysing and supporting innovators dedicated to reimagining the industry. Today it announced the eight change makers that will join its 2022 Global Innovation Programme.

Project to Transform Agricultural Waste into Green Fibers for Fashion Sector

“This ambitious project explores a new source of feed stocks for the fashion industry that, if scaled, will help drive both the agriculture and textile industry towards net-zero. We see great potential for these various agriculture waste streams that would otherwise have few secondary uses. By applying innovative technologies to develop natural fibers, we can diminish the pressure on existing natural fibers and shift away from unsustainable materials and sources,” says Katrin Ley, managing director, Fashion for Good.

Turning Waste into Black Pigments

Fashion for Good launched the Black Pigment Pilot project on Tuesday with partners Bestseller, Birla Cellulose, Kering and PVH Corp., in collaboration with Paradise Textiles, and innovators Graviky Labs, Living Ink and Nature Coatings. The project aims to validate and scale black pigments derived from waste feedstocks such as industrial carbon, algae and wood that could replace synthetic dyes and offer a more sustainable means of textile production with a lower carbon impact. [SUBSCRIPTION REQUIRED]

Fashion's Race for New Materials

“The race to develop new materials and processes is gaining momentum thanks to rapidly maturing technology and more substantial and deeper partnerships between brands and innovators who were often “slow on the action front””, said Georgia Parker, Head of Innovation at Sustainable Project Fashion for Good accelerator. This case study of Business of Fashion examines three innovations in the production of raw materials that are gaining momentum and providing opportunities for the fashion industry to reinvent the destructive materials and practices it has long relied on.

How a Kering and adidas-Led Consortium Aims to Dry Out Fashion’s Water Problem

Global accelerator Fashion for Good has announced a new consortium, the D(R)YE Factory of the Future project, backed by Kering and adidas, among others, aimed at reducing water use in textile production. The initiative is directed at accelerating the fashion industry’s shift to dry textile processing—methods that use little to no water, produce no wastewater and reduce overall energy use.

Is this the Future of Fashion?

Fashion for Good has launched the D(R)YE Factory of the Future initiative in a bid to clean up one of the most polluting processes in the industry. It is in the pre-treatment and colouration phases of textile production that the highest emissions of the fashion value chain are generated. To combat this, the new global consortium project led will bring together innovations that can transform these stages and pave the way for a seismic shift in processing techniques from wet to dry.

Fashion Players Team Up to Slash Textiles' Water and Carbon Footprint

From Deodorant to Digital Fashion: Design and Innovation Go Hand in Hand

Design is present on all levels of our society. With every design, it’s a matter for designers to stay one step ahead of us. They work now on the designs of tomorrow, seemingly requiring a crystal ball of some sort. But lacking that, an innovative mindset is crucial. Our Marketing & Communications Director, Anne-Ro Klevant Groen, discusses what design and innovation exactly mean for all the fashion industry stakeholders involved.

PVH, Bestseller Get ‘Priority Access’ to Ecovative’s Mycelium ‘Forager Hides’

PVH and Bestseller are first in line to trial Ecovative’s mycelium “Forager” hides in a new cooperative revealed today. Alongside the brands, Amsterdam-based nonprofit Fashion for Good (which Ecovative has been working with for the past three years) is also a strategic partner as Ecovative refines production.

Levi's in Pilot to Use Plant-Based Indigo

Fashion for Good is working with Levi’s Strauss & Co. and natural dye start-up Stony Creek Colors to pilot the use of plant-based indigo at scale in the denim’s industry supply chain. Stony Creek Colors will provide their IndiGold indigo dye to select denim mills used by the two companies to run performance trials, with the aim to have Levi garments dyed with IndiGold pre-reduced dye on the market by late 2022 or early 2023. [SUBSCRIPTION REQUIRED]

Fashion for Good Asia Builds Momentum

The Fashion for Good Asia Programme celebrated another successful year, sharing the highlights of 2021 at their Innovation Fest this week. Continuing to drive innovation across the region, Japanese fibre and textile manufacturer Teijin Frontier was officially welcomed as a partner, establishing a footing in East Asia where the programme is gaining momentum.

Fashion for Good’s Latest Project Spotlights Polyester Recycling

The writing is on the wall for polyester and its crude oil origins. Today, Amsterdam-based innovation firm Fashion for Good announced a new polyester-focused project, Full Circle Textiles Project – Polyester, borrowing from the findings in its Full Circle Textiles Project, which launched formally in September. The current project aims to validate and scale up promising technologies in polyester recycling. [SUBSCRIPTION REQUIRED]

Fashion for Good Turns to Polyester

Launch of Sorting For Circularity India

Project to Build a New Textile Waste Value Chain in India

Together with partners Adidas, Levi Strauss & Co, and PVH Corp, Fashion for Good is backing a new consortium project to understand both the pre-consumer and post-consumer textile waste streams in India, and to pilot sorting and mapping solutions. The Sorting for Circularity India Project aims to build an infrastructure towards greater circularity in the years to come.

The Fashion Industry Could Reduce Emissions—if It Wanted To

It’s common practice for apparel brands to hop from factory to factory in search of cost savings. This needs to change, but this requires the necessary funding. The Apparel Impact Institute and Fashion for Good estimate that it will take a trillion dollars in global investment to decarbonize the industry. Their new report calls it an investment “opportunity,” but brands are not exactly climbing over each other to get involved.

Fashion's Climate Goals Have a Funding Problem

The fashion industry cannot meet its COP26 climate commitments, nor can brands meet their individual goals to decarbonise, if they don’t address the major lack of funding needed to overhaul the supply chain, experts say. There’s a significant funding gap in fashion’s sustainability commitments, made clear in a new report estimating a $1 trillion deficit in reaching decarbonisation goals. We unpack where, why and how to fix it. [MEMBERSHIP REQUIRED]

Seaweed-Based Sway Against Single-Use Plastic Packaging

Annually, we use about about 500 billion plastic bags to store, transport, and protect garments, footwear and accessories. Less than 15% of polybags in circulation are collected for recycling, according to Fashion for Good. However, if the startup Sway has its way, more thin film packaging like polybags, retail bags, and wrappers will be compostable and even carbon negative. The packaging company makes seaweed-based, home-compostable replacements for plastic packaging, which even come in bright, cheerful colours.

GORE-TEX as Official Partner of Fashion for Good

The global initiative Fashion For Good has formally announced its partnership with technical textile supplier Gore Fabrics, home to the GORE-TEX brand. The cross-industry collaboration demonstrates the newly affiliate partner’s commitment to achieving its environmental goals and driving systemic change within the fashion industry. [ACCOUNT REQUIRED]

Gore Fabrics Joins Up with Fashion for Good

Technical textile supplier Gore Fabrics, which owns the GORE-TEX brand, has officially joined the Fashion for Good initiative. The newly affiliate partner said that it looked forward to the cross-industry collaboration through this partnership, demonstrating that they want to accelerate their sustainability efforts. Gore Fabrics officially partnered with Fashion for Good in early 2020 and is already participating in the recently announced Renewable Carbon Textiles Project, together with other partners from Fashion for Good. [SUBSCRIPTION REQUIRED]

Sustainable Fashion: Mycelium Leather, A Wood Pulp Dress, and Banana Fibres

It is clear to everyone involved that the current state of the apparel industry has detrimental impacts on our environment. A handful of brands and tech or bio-startups have been focusing on better solutions, but collaboration was lacking within the industry. However, ‘bridge builder’ Fashion for Good aims to put all these heads together. Its current exposition “GROW: the future of fashion”, demonstrates this by connecting young Dutch design talent with textile innovators and displaying the results in their Museum. [DUTCH ARTICLE, SUBSCRIPTION REQUIRED].

Sustainability Scanner: Making Fashion Good Again

Amsterdam-based fashion and textile innovation platform Fashion For Good’s funding initiative to aid sustainable manufacturing, the Good Fashion Fund (GFF) has signed its first deal with Pratibha Syntex Limited (PSL). The Indian textile and apparel manufacturer receives a $4.5 million long-term loan as part of the deal. Initiated in 2019, GFF provides long-term funding to the textile and apparel industry in Asia to achieve the Five Goods — Good Energy, Good Water, Good Materials, Good Lives, and Good Economy.

Good Fashion Fund To Assist Pratibha Syntex To Go Sustainable

Pratibha Syntex Limited, an Indian manufacturer, has struck an agreement with the Good Fashion Fund, a fund established by Fashion for Good to promote sustainable manufacturing practices. Pratibha Syntex’s anticipated capital expenditures for updating machinery and expanding sustainable equipment in several divisions will be supported by the $4.5 million long-term loans. The $4.5 million investment will be used to replace gear in the spinning, processing, and garmenting divisions, as well as to purchase new equipment to expand their operations and facilities.

Fashion for Good Celebrates The Success Of The Viscose Traceability Pilot Project

On World Rainforest Day, Fashion for Good celebrates the success of the Viscose Traceability Pilot Project, a consortium to trace sustainable viscose in clothing using the company’s blockchain tracing solution. TextileGenesis innovator. With around 30% viscose coming from threatened forests, the validation of TextileGenesis’ solution is an important step towards transparency in the value chain and ensuring that the fibers come from renewable sources.

From Textile Waste To Sound Insulation – The Acoustic Felt Made From Recycled Polyester

Hope still exists. Concerted efforts to remedy the reliance on plastic fibers has already begun, with the most recent launch of innovation consortiums like The Renewable Carbon Textiles Project in June with Fashion for Good, funded by the Laudes Foundation. In collaboration with global players including PVH Corp, the group are committed to developing replacements for fossil fuel-based fibers. By experimenting with PHA polymers, which provide a bio-based, marine and soil compostable alternative to materials like polyester, the project is pioneering viable alternatives.

GFA Figures Highlight Bangladesh Recycling Potential

Intrinsic to this is building robust recycling infrastructure within the country, which is the target of the Circular Fashion Partnership – an initiative the GFA launched late last year alongside Reverse Resources and the Bangladesh Garment Manufacturers and Exporters Association (BGMEA).

The claim comes as the project today welcomes its latest cohort of signatory brands, manufacturers, recyclers and organisations, including Primark, Gymshark, Benetton, Evrnu, Natural Fiber Welding and Fashion for Good.

Consortium Plans PHA Fibres For Fashion

Amsterdam-based Fashion for Good is launching the Renewable Carbon Textiles Project, bringing together a powerful consortium to accelerate the development of polyhydroxyalkanoates or PHA polymer fibres – a promising biosynthetic alternative to fossil based fibres with the potential to reduce carbon emissions in the fashion supply chain.

Sustainable Materials Are A Vision Of Fashion’s Future

The conglomerate has also partnered with the Amsterdam-based incubator Fashion for Good to help identify and grow start-ups working at the intersection of fashion and sustainability. Daveu points to Balenciaga’s October 2020 catwalk collection, comprised of 90 per cent recycled, upcycled or certified-sustainable materials, as an example of the changes brought about by these investments.

Sustainable Fashion: Fashion for Good And The Biomaterials Project

If you have ever wondered what biomaterials are, a trip to plan as soon as possible in this post-pandemic summer is in Amsterdam, where the Fashion for Good Museum has inaugurated a new exhibition dedicated to sustainable innovation in the field of materials, which sees protagonists fabrics from fruit peel , “skin” grown thanks to special fungi, spider silk, dyes produced by bacteria and algae.

Brands Back Bid To Boost Textile Recycling Premium Article

The Fashion for Good initiative is bringing together industry leaders – including Adidas, Bestseller, Zalando and Zara owners Inditex – in a new initiative aimed at increasing the recycling of waste textiles.

The Sorting for Circularity Project will use innovative near infrared (NIR) technology to analyse textile waste more accurately, while also mapping the capabilities of textile recyclers.

The Path To Scaling Reusable Packaging In E-commerce

To highlight the positive impact reusable packaging could generate, Fashion for Good, in partnership with Utrecht University and the Sustainable Packaging Coalition, have collaboratively authored a white paper, “The Rise of Reusable Packaging: Understanding the Impact and Mapping a Path to Scale”, presenting an overview of reusable packaging in the fashion industry and providing the industry with key considerations for wide scale adoption.

Innovating Sustainably in South Asia with Fashion for Good

Katrin Ley, managing director of Fashion for Good, on fashion and textile innovations in South Asia and why the Indian region matters

It has been a little over a year since Fashion for Good, the Amsterdam based platform for fashion and textile innovation, launched its South Asia Innovation Programme. Yesterday, April 13, the organisation announced its third batch of graduates from the region—a cohort of 10 innovators including three from India.

Fashion for Good South Asia Announces 3rd Batch of Innovators

Fashion for Good, the global platform for innovation, has selected ten new innovators to participate in the third batch of its South Asia Innovation Programme. The batch includes innovators from 8 countries adding Singapore and Indonesia to the roster. 3 out of 10 innovators are from India, who are making a global footprint with their sustainable approach.

The Future of Fashion Materials

The Dutch Fashion for Good Museum developed an in-house exhibition called GROW which shows biomaterials which might just be the future of fashion materials.

With the GROW exhibition, visitors are shown conventional biomaterials, like ecological (lab-grown) cotton, flax and hemp, but also innovative materials like fabric made of citrus peels, mushroom leather, spider silkand dye made with bacteria and algae.

Levi Strauss & Co. Joins Fashion for Good

Levi Strauss & Co. has long been an innovator in sustainable design and production practices. Many of the programs we talk about most often – Water<Less®, Screened Chemistry, cottonized hemp – came from within. It’s a record of scaling internal innovations that we’re quite proud of.

But we also know that we can’t work alone if we’re going to do our part to deliver solutions on an industry-wide scale or reach the ambitious goals we’ve set for ourselves. There are networks we need to tap into, innovations we can benefit from, and solutions we can help to scale. And that is precisely why we have joined Fashion for Good.

The Race for Fashion’s Leather Alternatives Heats Up

Ecovative wants to become the first to offer a plant-based leather alternative that’s ready to scale, and could up the ante in fashion’s race for leather replacements that are both more sustainable and higher quality, with a more attractive look and feel, than plastic-based vegan materials.

“Oftentimes with these different materials, you get a proof of concept that comes out and it takes time for these materials to then scale,” says Georgia Parker, innovation manager at Fashion for Good.

Fashion for Good Chooses New Innovators

Wasting no time, Fashion for Good has gotten the 14 start-ups recently selected for its accelerator program get started.

The latest roster was selected from among 22 entrepreneurial companies during Fashion for Good’s virtual selection day. The chosen start-ups are offering solutions for raw materials, processing, end-of-use, digital acceleration, plastics and impact tracking, among other topics. As participants, they are receiving mentoring, guidance and industry expertise to help scale up their technological businesses.

Building the Business Case for Circular Business Models Part 2: Rental

Both one-off rentals and rental subscriptions can be profitable circular business models in fashion, based on the 2019 analysis by Accenture and Fashion for Good, ‘The Future of Circular Fashion’. The economic analyses presented in the report are encouraging but we must note that the assessment was done at garment level, and does not fully take into account investments needed to operate and build these models to scale.

Katrin Ley of Fashion for Good Tells Us How They are Making All Fashion Good

Katrin Ley: For many years, I worked in the apparel and footwear industry, both on the strategy consulting side and the corporate side. And for the last couple of years, I was in the world of impact investing, investing in early-stage startups with circular ambitions.

The path that led me to Fashion for Good wasn’t that clear cut, and the career choices I made didn’t seem to connect for a while. I became more and more aware of the problems and challenges that face the fashion industry — the need for change as well as the potential solutions and innovations that exist.

Mountains Of Unsaleable Clothing Due to Lockdown Show That the Fashion Industry Can Be Much More Sustainable

“Online sales at retailers may have increased enormously, but many entrepreneurs say it is nowhere near what they would sell in their stores”, says Anne-Ro Klevant Groen, marketing and communication manager at Fashion for Good, a organization that focuses on innovation in the fashion industry. “There is still a large stock.”

The Single-Use Plastic Overhaul Is Coming For Fashion

The polybag, the clear plastic film used to store and transport clothes before reaching store, is one of fashion’s most ubiquitous packaging products: approximately 180 billion are produced each year and less than 15 per cent of those in circulation are collected for recycling. At the end of 2019, Fashion for Good, an Amsterdam sustainable fashion accelerator launched a circular polybag pilot programme with support from Adidas, Kering and PVH among others that tested Spanish technical recycling company Cadel Deinking’s polybags, which de-inks and removes adhesives from consumer plastic waste, allowing it to be recycled into new polybags for a circular alternative.

The Search for Fashion Supply Chain Transparency

In 2019, Zalando partnered with platform for sustainable innovation Fashion for Good on its “Organic Cotton Traceability Pilot”, which combines on-product authentication markers and blockchain technology to track organic cotton from farm to consumer. In December 2020, the German etailer started supporting Fashion for Good’s newest project, the Viscose Traceability Project, which uses blockchain technology to trace viscose. It also supports the Open Apparel Registry (an open-source map and database of global apparel facilities) to map garment facilities worldwide and allocate a unique ID to each facility.

How to Make Technology a Tool for Connection

For instance, Local Projects designed tech-enabled bracelets for Amsterdam-based Fashion for Good, a museum, store and think tank to educate on and combat climate change. The bracelets were made from plastic dredged from the city’s canals, and visitors could use them to make pledges about behavioural changes throughout the museum.

Cotton Grown in ‘Resource-Efficient’ Pilot Will Make Calvin Klein Fashion

Sourcing sustainable cotton—whether it’s regeneratively grown, recycled or organic—has become a common goal for fashion companies looking to prove an eco-minded ethos. Fashion for Good, a sustainability-focused organization whose partners include Adidas, Target and Chanel, is looking to investigate a new way to address some of the environmental issues associated with growing cotton, namely water and pesticide usage.

Consortium Around Fashion for Good Starts Pilot Project for More Efficient Cotton Construction

Fashion for Good is today launching a two-year pilot project that will experiment with more efficient technologies for growing cotton. The organization works together with fashion conglomerates Kering and PVH Corp, as well as textile producer Arvind Limited, it reports in a press release.

The Impact of COVID-19 on Sustainable Fashion Innovation

Even before the COVID-19 crisis, the fashion industry had begun to make changes, many of which have been accelerated by the crisis. Innovation, particularly in challenging times, has proven its relevance time and again to reinvigorate business as usual to achieve organisational objectives, and brands, manufacturers and retailers that are looking to innovation at this time, are better prepared to emerge stronger from the crisis.

Will Clothing In The Shops - After The Lockdown - Be Out Of Fashion?

Anne-Ro Klevant Groen, who works at Fashion for Good, an international innovation platform that strives for “circular fashion”:

“Many retailers now have a surplus of stock due to COVID-19, many stores are closed and clothing cannot be sold. However, online sales have skyrocketed at many retailers, but in general sales have gone down and unsold or not shipped clothing is a problem for many clothing brands. The solutions for this are, for example: selling in a later season, adjusting clothes and selling, reselling, renting out, recycling or ‘downcycling’.

The Hidden Obstacle to Circular Fashion: Chemicals

Fashion for Good, which launched an industry coalition last September to advance and promote textile recycling, said that can impair the economics of recycling — particularly when clothes contain chemicals that were once commonplace in fashion, but are now banned out of concern for health or environmental impacts — and managing director Katrin Ley says that’s another reason to eliminate the use of hazardous chemicals in new clothing.

Best of 2020: Sustainable reads

In the ‘New Cotton Project’, a consortium of brands, manufacturers, suppliers, innovators and research institutes will have to prove that circular, sustainable fashion “is not only an ambition, but can also be realized today”. The twelve participating fashion companies and brands include Adidas and the H&M Group, the Finnish biotechnology group Infinited Fiber Company, Aalto University, Fashion for Good, Frankenhuis, Inovafil, Kipas Textiles, REvolve Waste, Rise, Tekstina and Xamk.

Bio doesn't always mean better, need to validate sustainability claims

Bio-materials, however, remain an ill-defined category, with words such as bio-fabricated, bio-synthetic or bio-based used in relation to innovations in this space. Fashion for Good, a global platform for sustainable fashion innovations, teamed up with Biofabricate, a platform for bio-material innovators and brands, to conduct interviews of more than 30 global material innovators and consumer brands, and has compiled the learnings to help the fashion industry understand these various terms and innovations.

Fashion for Good celebrates success in South Asia

Dutch sustainability initiative Fashion for Good (FFG) has reported that its South Asia Innovation Programme has enjoyed a fruitful first year, with nine of its promising start-ups becoming graduates of the scheme.

Blockchain’s potential tested in new viscose project

Dutch sustainability initiative Fashion for Good has kick-started a Viscose Traceability Project which assesses blockchain technology’s performance in tracing the cellulosic fibre throughout the textile supply chain.

Why big brands are investing in sustainability start-ups

When Fashion for Good first launched four years ago, it started with a handful of brands and retailers as its corporate partners. Now, it counts manufacturers among its collaborators too. “We realised how important it was to get those upstream suppliers at the same table,” said Brittany Burns, director of strategy and development at Fashion for Good. “We felt like it was really important to create these opportunities for a cross-pollination of ideas, but [also] co-development across the industry.”

H&M and adidas join industry consortium partners delivering a blueprint for circular fashion

Industry giants Adidas and H&M are partners on this project and will work together to facilitate “the scale and volume needed to properly test this (technology),” said Infinited Fiber’s CEO Petri Alava during a recent video call. Representing Fashion for Good, who are facilitating stakeholder collaboration during the project, was Kathleen Rademan: “What we (at Fashion for Good) have noticed is, in order to get something like chemical recycling off the ground, more than one brand is needed.”

Back to the future: the role of technology in solving major challenges

In Robert Zemeckis’ film Back to the Future , the main characters navigate between the past and the future in a long process of discovery and transformation. Throughout these trips, Marty (one of the protagonists) has as main mission to repair the damage created by him in history. Although fiction and reality intersect more than we think, we still do not have the ability to travel through time or repair the damage that we have been creating throughout history. We know today that the great environmental or, in general, society challenges result from human intervention (global warming, social inequality, etc.). We also know that reversing these damages is particularly difficult because, unlike the characters in the film, we cannot change the past. We can, however, change the future and the consequences of our actions.

More job cuts: The cost of circular fashion

Circularity has become a priority for fashion, but labour experts are concerned that without deliberate planning, the industry’s efforts on the environment could cost millions of workers their jobs. They also worry that in cases where new jobs are created, they won’t offer paths to better livelihoods that the United Nations and others have called for employers globally to provide.

New report examines circularity potential in India

AMSTERDAM/MUMBAI – The Fashion for Good initiative has teamed up with the Circular Apparel Innovation Factory to draw up a report on the potential for circularity in the fashion and textiles industry in India. Entitled ‘State of Circular Innovations in the Indian Fashion and Textile Industries’, it aims to give a comprehensive overview of the sustainability opportunities and challenges across the Indian supply chain. Pointing out that India is both a global leader in manufacturing and also one of the largest consumer markets for fashion, it says the ongoing search for circular innovations is critical in terms of minimising environmental impact.

Zalando launches circularity pilot

Customers increasingly want to know more about the products they buy. They want transparent information and advice on how to care for their clothes to prolong their life. Currently only one percent of clothing is recycled into new materials, garments of today largely become the waste of tomorrow.

To learn how we can tackle this problem at scale and use technology to enable our customers to close the loop, Zalando has teamed up with sustainable fashion innovation platform, Fashion for Good, and Berlin based startup, circular.fashion, to develop the “redeZIGN for Circularity” capsule collection, which is now available to customers in all 17 Zalando markets. The capsule collection consists of five pieces and is produced by Zalando’s sustainability flagship label ZIGN. The collection offers customers the opportunity to learn more about the origin of products and how to extend the product’s life, bringing Zalando closer to its goal of applying the principles of circularity and extending the life of at least 50 million items by 2023 as stated in its do.MORE strategy.

Fashion for Good project champions chemical recycling tech

Sustainability initiative Fashion for Good (FFG) has initiated a new project which, with the support of a consortium of brands, manufacturers and industry organisations, will vie to scale promising chemical recycling solutions in cellulosic textile production. The Full Circle Textiles Project: Scaling Innovations in Cellulosic Recycling project brings together Kering, PVH Corp., Target, Birla Cellulose, the Laudes Foundation and Canopy, and creates an incubated environment in which the technologies of Infinited Fiber Company, Re:newcell, Tyton Biosciences, Evrnu and Phoenxt will be trialled in the manufacture of garments, with scope to scale such solutions.

NGOs unite to hasten sustainability in apparel industry

To accelerate sustainable transformation of the apparel and accessory industry, several leading subject matter experts have united as the Fashion Conveners. Spurred by the vulnerabilities the global pandemic brought forward, the group recognises the urgency to hasten transformational changes needed to reduce environmental and social impacts across fashion.

Why isn't sustainable fashion more affordable?

Sustainable fashion doesn’t have to cost a fortune, though, if there is enough demand out there. “There’s a perception that sustainable fashion is expensive – this isn’t necessarily the case,” says Brittany Burns, director of strategy and corporate development at non-profit Fashion For Good. “As [new] innovations become more mainstream, [this] drives the prices down. There’s a shift that has to happen.”

Fashion Industry Explores a Revolutionary Solution to Clean Wastewater

In order to look for new solutions and reduce the environmental impact of the wastewater treatment, Fashion for Good, a global initiative that is here to make all fashion good, in partnership with Arvind Limited, BESTSELLER, C&A and PVH Corp., provided business support, development funding and expertise to a pilot project, that involves the adoption of a new and improved wastewater treatment system to assess the feasibility of the solution. The game-changing wastewater treatment system developed by Scaling Programme start-up SeaChange Technologies was evaluated at the Treatment Plant of Arvind Limited near Gujarat, India. The SeaChange system was implemented over a period of three months to test the feasibility of wide-scale implementation of the system.

Fashion for Good welcomes 9 innovators for South Asia

Fashion for Good’s South Asia Innovation Programme has welcomed 9 start-up innovators into second batch of its Regional Programme. Focusing on innovations in raw materials, wet processing, packaging, end-of-use & digital acceleration, the new selection of innovators bring solutions into the Programme crucial to manufacturing and supply chains in South Asia. The second batch joins Fashion for Good’s global selection of start-ups driving the industry’s transformation towards a more sustainable, circular system.

The Good Fashion Fund is redesigning a dirty industry

Rabobank invests in the Good Fashion Fund, which provides loans for sustainable technologies to clothing manufacturers in India, Vietnam and Bangladesh. The objective? Systematic change. The loan from Rabobank (which equates to a value of 6.2 million USD) is a welcome addition to the fund. “We’re delighted,” adds fund director Bob Assenberg. “Rabobank is a leading, innovative commercial bank that focuses on sustainable financing, making it an ideal addition to the two other investors who have a relationship with the fashion industry.

India manufacturers see coronavirus as catalyst for good

In a webinar hosted by Fashion for Good, the global sustainable fashion innovation platform last week the panellists discussed how the global textile and apparel industry is beginning to look post-Covid and how it might emerge from the crisis. Sustainability, innovation and digitalisation are all seen as key to helping the Indian textile and clothing industry build back better from the Covid-19 pandemic, particularly with a focus on digital innovation. The South Asian manufacturing hub could also benefit from its indigenous environmentally friendly processes and models of textile production.

Questioning the sacrosanct, the new motto of fashion

In a recently conducted webinar conducted by Sujata Assomull, Founding Editor In Chief of Harper’s Bazaar, India, stake holders in the industry came together to map out the road ahead. On the panel was Dipali Goenka (CEO & Jt. MD, Welspun India Ltd), Punit Lalbhai (Executive Director, Arvind Limited) and Katrin Ley, Managing Director, Fashion For Good, who discussed the current scenario as an opportunity to inspire the industry to walk towards better productivity in fashion.

Sustainable bank invests in Good Fashion Fund

Sustainable banking company Rabobank has agreed to invest in the Good Fashion Fund which aims to provide capital for sustainable solutions in fashion industry supply chains. The fund invests in the adoption of high impact and disruptive technologies and circular innovations in the textile and apparel production industry, particularly in India, Bangladesh and Vietnam.

Good Fashion Fund welcomes Rabobank

Fashion for Good, the global platform for innovation, has received a funding from Rabobank. With a target size of $60 million, company’s current fund capital has reached around $19 million. This fund provides long term funding to apparel and textile manufacturers in India, Bangladesh and Vietnam and other Asian countries to implement impact technologies.

Will Fashion Ever Be Good for the World? Its Future May Depend on It.

The Covid-19 pandemic has put financial pressure on businesses, threatening their sustainability agendas. But aligning profit and purpose, and fulfilling responsibilities to the planet and communities of people beyond shareholders may matter more than ever to their long-term success.

Video: Is circular fashion the ultimate answer to current fashion practices?

Video-podcast ‘Act to make an impact’ is a series highlighting positive changes being made to the fashion industry. Titled “Is circular fashion the ultimate answer to the current failing fashion system?”, this edition is the 4th in the series. This podcast was recorded at Fashion for Good earlier this year.

Development and financing main concerns of fashion start-ups

The findings are a result of a survey conducted by Dutch sustainability initiative Fashion for Good which was shared with 105 innovators in its programmes to gauge the impact of the crisis on sustainable fashion startups and what support they need moving forward.

Exploring Sustainability in Fashion

Any big discussion about sustainable fashion must include the impact being made by Fashion for Good. Headquartered in Amsterdam, it runs accelerator programmes for early stage companies and scaleups reshaping the industry and – since 2018 – it has been home to an amazing interactive museum where visitors can experience the future of fashion. FFG is also at the heart of a growing communication ecosystem dedicated to inspiring actions that can fast-track the transition. And next week it is hosting an online event: Unpacking the Shifting Role of Sustainability in Fashion

Peter C. Leferink: “What we used to call ‘fashion’ is worn out, beaten down and broken.”

7 experts share their thoughts on what steps they would like to see the fashion industry take now and post-coronavirus.

Pandemic May Have Varying Degrees of Impact on Sustainable Fashion Startups

Though the COVID-19 pandemic may bring a period that stalls innovation as businesses and the supply chain strive to restore themselves, Fashion for Good managing director Katrin Ley says innovation is essential to “reinvigorate business” and “emerge stronger” from this critical period.

23 Sustainability Efforts of the Fashion Industry in March 2020

London-based commercial recycling company First Mile has partnered with sustainable fashion innovation platform Fashion for Good to tackle plastic polybag waste in the fashion industry with a new London-based pilot scheme.

Podcast: Are Polybags Still in Fashion?

Ashley Holding, innovation manager at Fashion for Good and Adam Gendell, associate director of GreenBlue’s flagship project, the Sustainable Packaging Coalition, discuss findings from their joint whitepaper.

Fashion for Good Hosts First Virtual Selection Day

Due to current circumstances surrounding Covid-19 pandemic, Fashion for Good held its first virtual Selection Day, hosting international audience of corporate partners and innovators through an online webinar.

Startups Changing the Face of Fashion

Thirteen international startups reshaping the fashion industry have been selected for the internationally-renowned Fashion for Good accelerator. For the first time, due to the deadly COVID-19 pandemic, the seventh batch were picked via a virtual selection day.

Trending in Fashion: what’s outside also counts

Meanwhile, Fashion for Good is on a mission to produce a closed-loop solution for the ubiquitous polybags inherent in fashion retail and e-commerce. Through its Circular Polybag Pilot, launched in December, the collective aims to minimize the use and impacts of the roughly 180 billion virgin polybags produced to store, transport and protect garments, footwear and accessories each year.

Fashion for Good Taking Sustainable Ideas Mainstream

By connecting investors with large-scale manufacturers, Fashion for Good is working on making the industry greener.

Fashion for Good Courts Nine South Asia Innovators In new Program

Fashion for Good kicked off its South Asia innovation program last week, selecting nine innovators “at the cutting-edge” of fashion’s circular transformation.

Podcast: The price of sustainability – $300bn

Katrin Ley from Fashion for Good and Catharina Martinez-Pardo from the Boston Consulting Group (BCG), the authors of a new report on what it will cost to meet the industry’s sustainability goals, join Mike Schragger from the Sustainable Fashion Academy.

Interview with Rogier Van Mazijk & Catharina Martinez Pardo

Innovations emerging in the fashion industry in response to sustainability pressures present unprecedented investment opportunities, which Boston Consulting Group (BCG) and Fashion for Good estimate at $20 billion to $30 billion annually, according to their new report. In conversation with Richa Bansal, Fashion for Good’s Finance Director Rogier Van Mazijk and BCG Principal Catharina Martinez Pardo throw light on the findings.

Pilot Project to Tackle Plastic Polybag Waste in Fashion Industry

Recycling company First Mile has partnered with global sustainable fashion innovation platform Fashion for Good on a new pilot scheme that aims to tackle the issue of plastic polybag waste in the fashion industry.

Fashion for Good Expands Polybag Recycling Work

Global sustainability initiative Fashion For Good (FFG) has partnered with UK recycler First Mile to streamline plastic polybag recycling efforts in London, as it expands the outlook of its Plastics Packaging Project.

Just a Mere $20B to $30B a Year to Transform the Industry, According to Report

It’s going to cost $20 billion to $30 billion a year to live out the fashion industry’s sustainability promises. That’s the amount needed to be deployed per year toward the development and scaling of disruptive innovations and business models in the fashion industry in order to see a significant “step change” by 2030, according to a report from Boston Consulting Group and Fashion for Good.

6 ways to drive funding to transform the fashion industry

In 2020, sustainability is at the top of the fashion industry’s agenda. The industry’s environmental and social impacts are well documented. Under growing consumer and regulatory pressures, industry leaders are recognising the urgent need to move towards responsible practices. The question now is how the industry will transform to achieve a sustainable operating model.

How Circular.fashion is helping the fashion industry become circular in innovative ways

In conversation with co-founder of Circular Fashion: Ina Budde

Circular.fashion may be at the forefront of the road to circularity, but who does Budde look up to. Who or what inspires her during her work? Fashion for Good comes up, mainly because it brings together large and impactful companies and innovators in a place that is not about competition. “We look up to all these initiatives Together, after all, the best and biggest impact can be made and development can be accelerated.

Fashion for Good launches pilot to make circular polybag

Fashion for Good in partnership with Adidas, C&A, Kering, Otto Group, PVH Corp, and Cadel Deinking, has launched a new pilot project—The Circular Polybag Pilot, which will explore a solution to reduce use and impact of virgin polybags in fashion industry. The pilot is a first in apparel industry to trial a truly circular solution for polybags.

Fashion for Good lance un project pilote pour produire un emballage circulaire

L’initiative Fashion for Good lance un nouveau projet pilote, le Circular Polybag Pilot qui explorera une solution qui vise à réduire l’utilisation et l’impact des emballages polybags vierges dans l’industrie de la mode. Orchestré par Fashion for Good en partenariat avec adidas, C&A, Kering, Otto Group et PVH Corp., avec Cadel Deinking, un innovateur du programme Fashion for Good Accelerator, le pilote est une première dans l’industrie du vêtement à tester une solution véritablement circulaire pour les polybags.

Fashion for Good successfully traces organic cotton

An Organic Cotton Traceability pilot has successfully combined on-product markers and blockchain technology to track organic cotton from farm to consumer, a first in apparel industry. The pilot is a collaboration between Fashion for Good, C&A Foundation & Organic Cotton Accelerator, supported by C&A, Kering, PVH Corp, Zalando and Bext360 as technical partner.

Fashion disruptors can reshape sector

The Fashion for Good-Plug and Play Accelerator Programme is helping to facilitate a sustainable revolution across the industry. In nurturing and advancing a conveyor belt of startups driven by a passion to deliver a clean future for fashion, it is fast tracking transformations that are good news for people and planet.

Hong Kong Fashion Summit 2019: Sustainable fashion on the rise in Asia

Global sustainability initiative Fashion for Good appeared at the Hong Kong Fashion summit yesterday to showcase a new investment fund dedicated to driving sustainable fashion in Asia.

The team at Fashion for Good have launched the “Good Fashion Fund” to initiate systemic change in the apparel and footwear supply chain, through investing in innovative technologies focused in India, Bangladesh and Vietnam. Fashion for Good, based in Amsterdam, is partnering with corporate fashion leaders at the C&A Foundations, impact investment firm FOUNT and Hong Kong-based The Mills Fabrica to début the fund. Aiming to disrupt the manufacturing culture in south-east Asia, the fund was revealed at the Hong Kong Fashion Summit 2019.

Good Fashion Fund launched

A new funding platform initiated by Fashion for Good (FFG) has launched today that will focus on mobilising budding innovations within the textiles industry by providing the crucial capital needed to scale up such solutions.

Sustainable Fashion Ecosystem in India Gets a Boost as Fashion for Good Launches its Asia Programme

Innovative startups from India with disruptive sustainability solutions applicable to the fashion supply chain will now have the opportunity to be part of a Asia innovation programme launched by Fashion for Good, supported by Intellecap.

Around and around on circularity

I’m just back from two weeks in Europe, where the conversation about circularity is going on in earnest. Not surprisingly, the conversation has hot spots, such as the Netherlands, where the national government has stated a goal of achieving a circular economy by 2050 (and a 50 percent reduction in the use of materials, fossil fuels and metals by 2030).

Fashion For Good Extends Reach in South Asia With Callout to Innovative Start-ups

To improve the carbon footprint of the fashion industry, the group wants a greater presence in dominant countries for fashion manufacturing. Disruptors Welcome: The sustainability-minded Fashion for Good is expanding to South Asia with the launch of a regional innovation program.

Are you a fashion disruptor in Asia?

Fashion For Good is launching a South Asia Innovation Programme to help sustainable fashion startups in the region reach their full potential. Amsterdam-based FFG is transforming the industry globally, with the support of the C&A Foundation, and a host of corporate partners, including C&A, adidas, Kering and PVH Corp.

Lancering Dutch Circular Textile Valley: op naar een circulaire modebranche

Met de onthulling van een circulair T-shirt is de lancering van Dutch Circular Textile Valley – door de organisatie nu al liefkozend DCTV genoemd – een feit. De DCTV is in het leven geroepen om de transitie naar een circulair kleding- en textielsysteem te versnellen. Het shirt met daarop een circulair logo werd in ontvangst genomen door experts van Fashion for Good, Circle Economy, ABN Amro, MVO Nederland, Het Groene Brein en Modint. Samen vormen zij het versnellingsteam achter het nieuwe initiatief DCTV.

New report makes business case for circular fashion

A new report has been published by Fashion for Good and Accenture Strategy, exploring the financial viability of circular business models in the fashion industry.

Circular fashion: a model for success

The fashion industry can profit from moving to circular business models. That’s the clear message from a new report jointly penned by Fashion for Good and Accenture Strategy.

Arvind joins Fashion for Good

Textile manufacturer Arvind Limited is the latest company to join the global sustainability initiative Fashion for Good. With Arvind, a global leader in apparel manufacturing and trailblazer in advanced materials, the Fashion for Good Innovation Platform gains a well-experienced partner “committed to testing and implementing sustainable innovations” according to a press release published today.

5 Minutes With…Georgia Parker from Fashion for Good.

We live in an age of unprecedented demand on our global resources. The fashion industry is one of the world’s largest polluter, just behind oil. Fashion for Good is a platform for sustainable fashion innovation. Its mission is to bring together the entire ecosystem to make fashion a force for good. Liz Gyekye, Deputy Editor at Bio Market Insights, catches up with Georgia Parker, innovation manager at Fashion for Good.

Big Closet Small Planet - With Michael Schragger

Do you get excited when hearing about breakthrough sustainability apparel innovations – such as fibers made from fruit waste or blockchain technology being used to track and trace the origin and content of your clothing? Do you sometimes wonder if these breakthroughs are too good to be true? Greg Stillman and Rogier van Mazijk work with visionary entrepreneurs and impact investors every day.

Circle Economy, Fashion for Good partner for circular shift

A strategic partnership has been established between industry innovation hub Fashion for Good and Switching Gear, a project set up by Circle Economy. The initiative has been started with the aim of accelerating re-commerce and rental business models within the apparel sector, and will collaborate with six brands to design and launch pilots of new business models by 2021.

Fashion For Good: five recent milestones

To transform the fashion industry, global fashion retailer C&A together with its corporate foundation, the C&A Foundation, launched the Fashion for Good Centre in Amsterdam two years ago, with the aim of transforming the fashion industry, driving its transition to a circular economy and bringing industry players together to “reimagine how fashion is designed, made, used and reused”.

12 Emerging Brands Melding Style With Sustainability

A growing number of young brands are putting sustainability at the center of their business models. As part of WWD’s special Earth Day coverage, here are 12 emerging green designers.

Action Speaks Louder Than Words, According to Sustainability Specialists

Sustainability is a prevailing topic with fashion executives, but consumers need pragmatic advice — not statistics — to take action. In the ongoing battle to try to make consumers more sustainable, statistics are often the weapon of choice. But as for what will actually make shoppers change their everyday behavior and adopt more planet-saving habits, that on-the-ground strategy encompasses more varying directives.

Stella McCartney Is Looking For Green-Minded Collaborators To Radically Shake Things Up

The ethical pioneer and her head of innovation, Claire Bergkamp, discuss how to turn a commitment to the planet into a stylish, profitable proposition in Vogue’s Get Your Greens series.

Can Recycling Fix Fashion's Landfill Problem?

For nearly 20 years Adidas AG has pursued an environmental and technological holy grail: a sneaker that can be recycled and reused in new shoes without any waste. It’s a feat of design and engineering that has proved elusive.

Part 3: Creating transparency

“For us at Supplycompass, it’s about bringing supply chains into the 21st century via vetted online marketplaces and the digitisation of design development, sourcing and production management methods. Once every player in a supply chain is working from the same platform, the interconnectivity and purchasing that happens throughout the system will allow brands much greater traceability and certainty on compliance and impact”

10 Tips to Starting a Career in Sustainability

Awareness and information around sustainable practice and jobs are few and far between; reliable resources are limited; and learning to divorce personal ethics with professional practice can be a challenge. Here, Bergkamp shares her insight on how best to start a career in fashion’s growing sustainability sector.

Conscious and Sustainable Fashion

In episode four of Impact Unpacked, Chloe and Helen dive into fashion, style, clothing – they chat about how fast or cheaply made fashion negatively impacts the environment, and explore the many creative initiatives being taken to provide style to consumers while being good for people, and the planet.

Fashion for Good: leading the race against fast fashion

The fashion industry is one of the largest polluters in the world. In an effort to look for more sustainable ways of working, the Amsterdam-based non-profit platform Fashion for Good aims to connect and inform all major players in the field, including consumers, through its impressive office, event space and museum. Fashion for Good’s Communications Manager, Anne-Ro Klevant Groen, explains why the pace must be stepped up to stamp out fast fashion.

Can Blockchain Technology Make Fashion More Transparent?

At Good On You, we firmly believe in transparency. We think it is the first step towards accountability and making the fashion industry more ethical and sustainable. But how did we come to this current state where we know nothing (looking at you, Jon Snow) or at least very little about how our clothes are made?

Meet The 10 Innovators Reshaping the Fashion Industry For Good

Today Fashion For Good announced their fifth batch of innovators who will be joining their Plug and Play Accelerator. The selected ten innovators will be partaking in a twelve-week programme that includes mentorship and business development opportunities with Fashion For Good’s corporate partners.

Trending: UN, Circular Innovators Continue Mission to Slow Down Fashion

A handful of new initiatives, products and innovations continue the attack on fashion’s wasteful and environmentally and socially destructive practices from a variety of angles.

Fashion for Good reveals fifth batch of companies joining its accelerator program

A new wave of companies looking to make fashion more sustainable has joined Fashion for Good’s Plug and Play Accelerator program, which provides them with a twelve-week curriculum including mentorship and business development opportunities from Fashion for Good’s corporate partners C&A, Adidas, Bestseller, Galeries Lafayette, Kering, Otto Group, PVH Corp, Stella McCartney, Target and Zalando.

Fashion for Good welcomes new group of innovators

AMSTERDAM – A fifth batch of innovators have joined the Fashion for Good-Plug and Play Accelerator, as ten entrepreneurs were selected from hundreds of applicants.

They will undertake a twelve-week curriculum which includes mentorship and business development opportunities, with the aim of driving market validation and priming the technologies for implementation at scale.

New initiative closes on full organic cotton traceability

AMSTERDAM – The developers of a new tracing system say they are confident they will soon be able to fully trace organic cotton from the farm right through to the consumer. Pressure for greater transparency and sustainability in the fashion industry is intensifying, with consumers more aware than ever of the ethical and environmental impact of fashion, while governments are beginning to demand accountability from brands and retailers for their supply chains.

This Blockchain Startup Is Partnering With Fashion Giants To Make Organic Cotton Traceable

Consumer demand is driving fashion outlets to use more organic cotton, pushing the commodity to a global market of over $15 billion. Despite double-digit growth in production year over year, companies struggle to meet that demand, and the fragmented nature of the supply chain makes it difficult for manufacturers to know if the cotton they’re buying is actually organic—or just a knockoff.

Outdoor brand Norrøna partners with Fashion for Good

Norwegian outdoor brand Norrøna has been announced as the latest company to join forces with Fashion for Good, as the sustainable fashion initiative continues to gain industry traction by working with an ever-growing pool of apparel sector organisations to support innovation.

Transparency the topic of latest Fashion for Good collection

AMSTERDAM – Sustainability initiative Fashion for Good (FFG) has announced the theme of its next capsule collection which will hone in on transparency within the industry. The ‘Naked’ collection – only the second of its kind to be held in FFG’s museum which opened in October – will comprise garments manufactured by six new partnering brands which purport to prioritise sustainability and circularity in their supply chains.

A journey towards sustainable fashion

The Fashion for Good museum in Amsterdam is educating people about where their clothes come from and what types of sustainable options are out there.

Fashion for Good Introduces Reformation and Allbirds to Dutch Consumers

Dutch consumers will get their first taste of Los Angeles transparent label, ReformationJeans, at the Fashion for Good Experience.

Beginning Feb. 1, Reformation will be one of six sustainable brands included in Fashion for Good’s new capsule collection focused on transparent brands, called “Naked.”

The Amsterdam-based interactive museum is the first dedicated to sustainable fashion innovation. The “carefully curated” selection of brands—Reformation, A.BCH, Allbirds, ASKET, la fille d’O and Swedish Stockings—will be featured in the museum’s contemporary retail space.

Fashion for Good joins forces with Bestseller

Bestseller, the intentional fashion company with more than 20 brands in its portfolio including Vero Moda and Jack and Jones, has announced that it is partnering with innovative platform Fashion for Good to help bring “game-changing” circular innovation to supply chains.

Bestseller partners with Fashion for Good

AMSTERDAM – International fashion house Bestseller has entered a strategic partnership with Dutch initiative Fashion for Good (FFG) as the pair look to drive the mass fashion market’s adoption of sustainable, circular technologies.

Fashion for Good kündigt Partnerschaft mit Bestseller an

Fashion for Good, die in Amsterdam ansässige Plattform für nachhaltige Mode, gab heute bekannt, dass sie sich mit dem dänischen Modekonzern Bestseller zusammenschließt.

Circular fashion a BESTSELLER