What are biomaterials in fashion?

Image via Pexels.

THE IMPACT OF MATERIAL PRODUCTION

According to McKinsey & Co.’s Fashion on Climate report, the fashion industry was responsible for 2.1 billion tonnes of metric tons of GHG emissions in 2018 — about 4% of the global total and around the same quantity of GHGs per year as the entire economies of France, Germany and the United Kingdom combined.

Tier 4, where raw material production takes place, can constitute as much as two-thirds of a brand’s carbon footprint.1 Aligning with the global 1.5°C pathway necessitates a 45% reduction in raw material production by 2030.2 This transition hinges, in part, on the adoption of innovative materials that do not rely on virgin fossil fuels. Despite this, virgin fossil-based synthetic fibre volumes continue to increase, veering the industry further away from the desired direction. Under this current trajectory, the fashion industry will miss the 1.5°C pathway by 50%.3

Given the record-breaking temperatures and climate disasters experienced over the last few years, the task is clear: the industry must transition from energy-intensive materials to fully circular, lower-impact solutions, which include biomaterial innovations. These cutting-edge biomaterial innovations can play a pivotal role in reducing the industry’s impact, frequently incorporating waste inputs and employing processes that can be inherently more efficient in terms of water, chemicals, and energy usage.

NAVIGATING THE TERMINOLOGY

The term “biomaterials” has become increasingly prevalent amongst brands and consumers alike, serving as a shorthand for materials that have something of a biological association. The world of biomaterials, however, is expansive and encompasses diverse materials, production processes, and outputs. It’s important to approach these terms carefully and avoid blanket statements, especially as “bio” does not always mean better. To address this linguistic uncertainty, Fashion for Good, in collaboration with Biofabricate, co-authored a report in 2020 titled ‘Understanding ‘Bio’ Material Innovations: a primer for the fashion industry’.

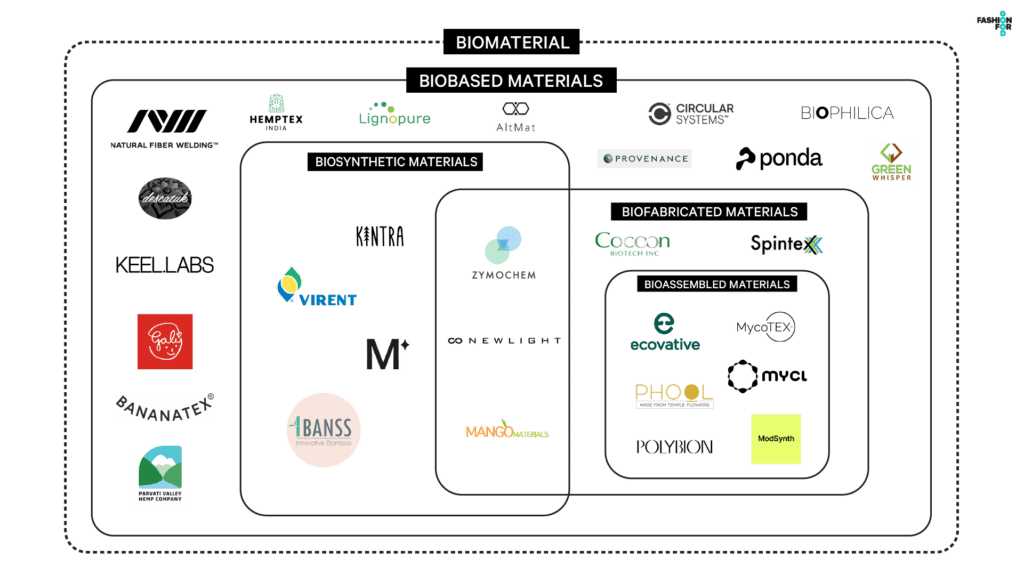

BIO-101: UNDERSTANDING THE DIFFERENT “BIO” TERMS

Biomaterials, also known as biobased materials, is a broad term that refers to anything with a biological connection. This includes lots of common materials we use today, such as cotton, linen, and wool, as well as more cutting-edge innovations such as jackets made from spider silk (e.g. Spiber’s Moon Parka) or dyes produced by bacteria (e.g. Colorifix).

Biomaterials are wholly or partially derived from plants, trees, or animals. These are, for example, traditional options like pure cotton and animal leather, as well as innovative “leather” alternatives made from fruit or green waste which can (but don’t have to) be combined with synthetic polymers.

Generally, when we look at materials it can be useful to assess them across a couple of key categories:

1) Feedstock: what is the material made of and how is it created or cultivated?

2) Process: how is the material made e.g. with the help of bacteria, through a mechanical or chemical process and does it cause any toxic waste streams or by-products?

3) Product: how much of the material is in the final product, is it blended with something else and does it have the desired characteristics such as performance and durability?

4) End of Use: what happens when it can no longer be worn? can it be recycled or would it be biodegradable? If so, in which conditions?

To get a better understanding of what this entails in practice, let’s take a closer look at the most widely used terms applied in the world of biomaterials:

- Biosynthetic materials: This term describes synthetic materials either made via (catalytic) conversion of biological sources (like biomass) or created in fermentation processes utilising living organisms (biosynthesis). The result is a material termed “biosynthetic”, like a biobased PET or nylon.

- Biofabricated materials: Also known as ‘biomanufactured’ materials, these are crafted by living cells or microorganisms like bacteria, yeast, and mycelium. Examples include recombinant silk or biofabricated ingredients for biosynthetics, and advancements from companies like Spiber and Mango Materials.

- Bioassembled materials: A specific type of biofabricated material where the whole macroscale structure has been grown directly by the living microorganism. Examples include mycelium or microbial cellulose materials that function as leather alternatives from companies like Ecovative or Polybion.

BIOMATERIAL’S PATH TO SCALE

For biomaterials to scale and be commercially available, they must achieve cost competitiveness while meeting essential performance benchmarks. This task is particularly daunting for emerging biomaterials competing against established counterparts like nylon or polyester. Biomaterials offer a viable route for companies to reach ambitious sustainability targets, but the industry’s hesitancy to pay a “green premium” is still a challenge. That being said, while certain performance properties are important to reach, some of these new biomaterials cannot be seen as a replacement for their traditional counterparts and will therefore never have the same properties. Instead, they have to be viewed as a new material category, with their own unique properties and design possibilities.

Shifting industry norms to embrace these new material properties, as well as longer-term commitments and a willingness to invest in premium-priced sustainable materials is crucial. Additionally, policy and legislation can play a pivotal role in expediting the industry’s transition to sustainable materials, urging companies to consider the significant environmental impacts of current production processes and incentivising investments in the scalable development of biomaterials.

OUR INNOVATORS

There are already many exciting innovations focusing on biomaterials, many of which are part of our Innovation Programme:

- Virent (Biosynthetic)

- Kintra Fibers (Biosynthetic)

- Ponda (Biobased)

- Lignopure (Biobased)

- Phool (Bioassembled)

- IBANSS (Biosynthetic)

- MYCL (Bioassembled)

- MycoTex (NEFFA) (Bioassembled)

- Polybion (Bioassembled)

- Spintex (Biofabricated)

- Modern Synthesis (Bioassembled)

- Biophilica (Biobased)

- Natural Fibre Welding (Biobased)

- Provenance Biomaterials (Biobased)

- Newlight Technologies (Biosynthetic & Biofabricated)

- Ecovative Design (Bioassembled). Learn more about the innovator here or read our interview with Gavin Mclntyre, Co-founder and CCO here.

- Keel Labs (Biobased)

- Mango Materials (Biosynthetic & Biofabricated)

- Galy (Biobased)

- Cocoon Biotech (Biofabricated)

- Matereal (Biosynthetic)

- Zymochem (Biosynthetic & Biofabricated)

- FARFARM (Biobased)

- Algaeing (Biobased)

- Orange Fiber (Biobased)

- Flocus (Biobased)

- Bear Fiber (Biobased)

- AltMat (Biobased)

- Circular Systems (Biobased)

- Bananatex (Biobased)

- Green Whisper (Biobased)

- Chlorohemp (Biobased)

- HempTex India (Biobased)

ENGAGING WITH INDUSTRY INSIGHTS

We often draw inspiration and knowledge from specialist organisations and individuals across diverse fields, consistently challenging and broadening our perspectives. Here’s a list of great sources we’ve used for this piece:

- Apparel Impact Institute. (2023). Taking Stock of Progress Against the Roadmap to Net Zero.

- Fashion for Good & Biofabricate. (2020) Understanding ‘Bio’ Material Innovations: a primer for the fashion industry.

McKinsey & Co. (2020.) Fashion on Climate. - Textile Exchange, BCG & Quantis (2023). Sustainable Raw Materials Will Drive Profitability for Fashion and Apparel Brands.

- Textile Exchange. (2023). Materials Report 2023.

1. Textile Exchange, BCG, & Quantis (2023). Sustainable Raw Materials Will Drive Profitability for Fashion and Apparel Brands. Read here.

2. Textile Exchange. Materials Report 2023. Read here.

3. McKinsey & Co. Fashion on Climate (2020). Read here.

Other Articles

In Conversation with CuRe Technology: How Can We Create a Fully Circular Polyester Chain?

Meet the Innovator: CuRe Technology