Fashion for Good Asia Builds Momentum With New Partner, Consortium and Innovations

Asia innovator KBCols Sciences collaborated with Dutch brand Hul le Kes to dye their latest collection. Featured in the Fashion for Good Museum in Amsterdam. Credit Alina Krasieva

24 November 2021

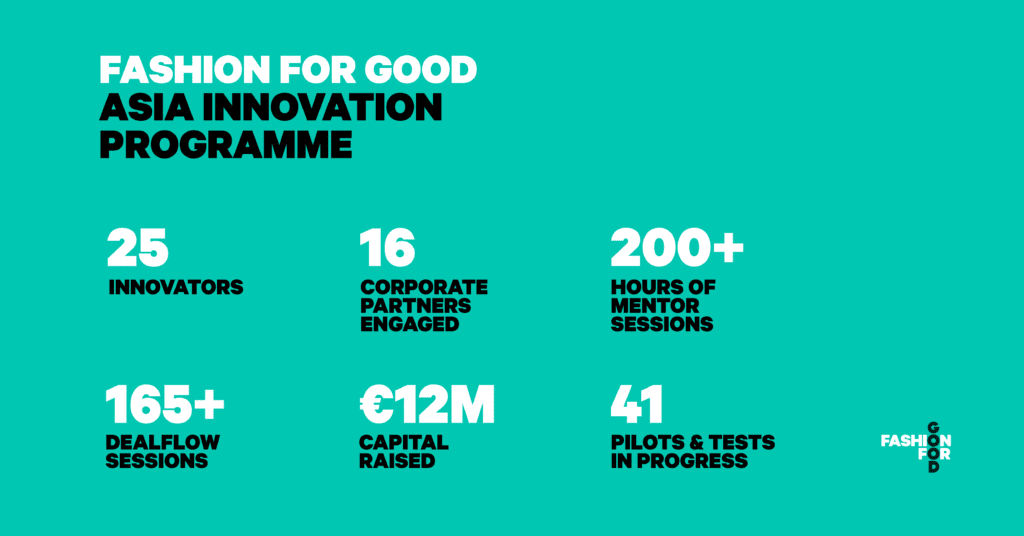

MUMBAI – The Fashion for Good Asia Programme celebrated another successful year, sharing the highlights of 2021 at their Innovation Fest this week. Continuing to drive innovation across the region, Japanese fibre and textile manufacturer Teijin Frontier was officially welcomed as partner, establishing a footing in East Asia where the programme is gaining momentum.

The Innovation Fest served as an occasion to mark the graduation of its recent batch of innovators and to announce the launch of an industry convening project, Sorting for Circularity India, in collaboration with eight corporate partners.

“We are extremely proud of our accomplishments with the Asia Programme in just two short years; in building a solid foundation in South Asia with our partners Arvind, Birla Cellulose and Welspun and now establishing a relationship in East Asia with Teijin Frontier, who we warmly welcome to Fashion for Good. We look forward to strengthening our presence in 2022 and are excited to collaborate together on industry changing projects.” – Katrin Ley, Managing Director at Fashion for Good

GAINING GROUND ACROSS ASIA

Fashion for Good is excited to welcome its newest partner -Teijin Frontier. Part of the Japanese based Teijin Group, Teijin Frontier, is an industry leading producer of innovative raw materials including synthetic fibres, yarns and apparel. With long standing commitments to tackle climate change in the areas of circular economy, reduction of emissions, removal of hazardous chemicals, and efficient management of water resources, Teijin Frontier is a pivotal partner to the Fashion for Good network of global players and portfolio of innovators from across the world.

After establishing a firm foothold in South Asia with partners Arvind Limited, Birla Cellulose and Welspun India, the addition of Teijin Frontier expands not only the geographical span of activities of the platform farther East, but also the breadth of material and industry expertise.

“We’re happy and proud to be a member of Fashion for Good; to accelerate the environmental innovations together and to contribute with our best technologies and accumulated knowledge of polyester.” – Yukihiro Shigemura, General Manager, Technology & Production Division at Teijin Frontier

BUILDING A NEW TEXTILE WASTE VALUE CHAIN IN INDIA

Today, Fashion for Good launches the Sorting For Circularity India Project, a consortium project to understand both the pre-consumer and post-consumer textile waste streams in India, and to pilot sorting and mapping solutions.

Building on the successful consortium framework, the project brings together industry players including partners adidas, Levi Strauss & Co., PVH Corp., Arvind Limited, Birla Cellulose and Welspun India. A key technology partner for the project is Fashion for Good innovator Reverse Resources who provides the analysis of the pre-consumer textile waste streams in addition to designing and running the pre-consumer pilot. The project is supported through catalytic funding provided by Laudes Foundation and aims to build an infrastructure to drive the scaling of chemical recycling technologies towards greater circularity.

Read more about the project here

SCALING INNOVATIVE TECHNOLOGIES IN ASIA

The end of the year also marks the graduation of 18 innovators from Batch 2 and Batch 3 of Fashion for Good’s Asia Programme in 2021. Spanning eight countries, they represent technologies focusing on solutions across the fashion supply chain and have made tremendous progress through pilot projects with industry partners, fundraising and overall product development. Some standout successes include:

MYCL, an innovator focused on providing leather alternatives with their low-impact mycelium leather, partnering with Zalando and Bonprix (Otto Group) to pilot their innovation.

KBCols Sciences, a technology that extracts natural colours from renewable biomass that can be applied to textiles, has completed the first phase of their pilot with Kering and is now testing dyeing textiles in bulk.

In addition to commercial opportunities with industry partners, the innovators secured various investments to further scale operations. Fashion for Good invested in both Graviky Labs and MYCL, supporting their activities in piloting their technologies with Fashion for Good partners. Innovators Nordshield, Phool and Lucro secured external investments, and Danish innovator Aquaporin, who enrolled in the programme to support their Asia expansion activities, is listed on NASDAQ Copenhagen.

“It has been an exciting journey with Fashion for Good over this year. We received access to industry experts and advisors with Fashion for Good proactively curated pilot opportunities and helped us secure multiple partnerships. The life cycle assessment has been very useful in understanding our footprint in the industry. We are very grateful for this year of learning, exposure and continued support and look forward to completing pilots in the coming year and sharing the learnings with the wider industry.” – Adi R. Nugroho, CEO and Founder at MYCL

Other Articles

In conversation with Smartex: Explore Smartex’s AI-driven solutions transforming quality control and reducing waste

Fashion for Good and Textile Exchange Team Up to Trace Textile Waste