What is textile processing? Understanding the fashion supply chain and its environmental impact

Image by Ethan Bodnar.

1 March 2023

AN OVERVIEW OF PROCESSING

The impact of today’s fashion industry has far reaching environmental consequences. And while raw material production and end of use may spring to mind, the processing stage of the supply chain, which includes pre-treatment, colouration (dyeing and printing) and finishing, is often overlooked as a critical area for pivotal and positive change.

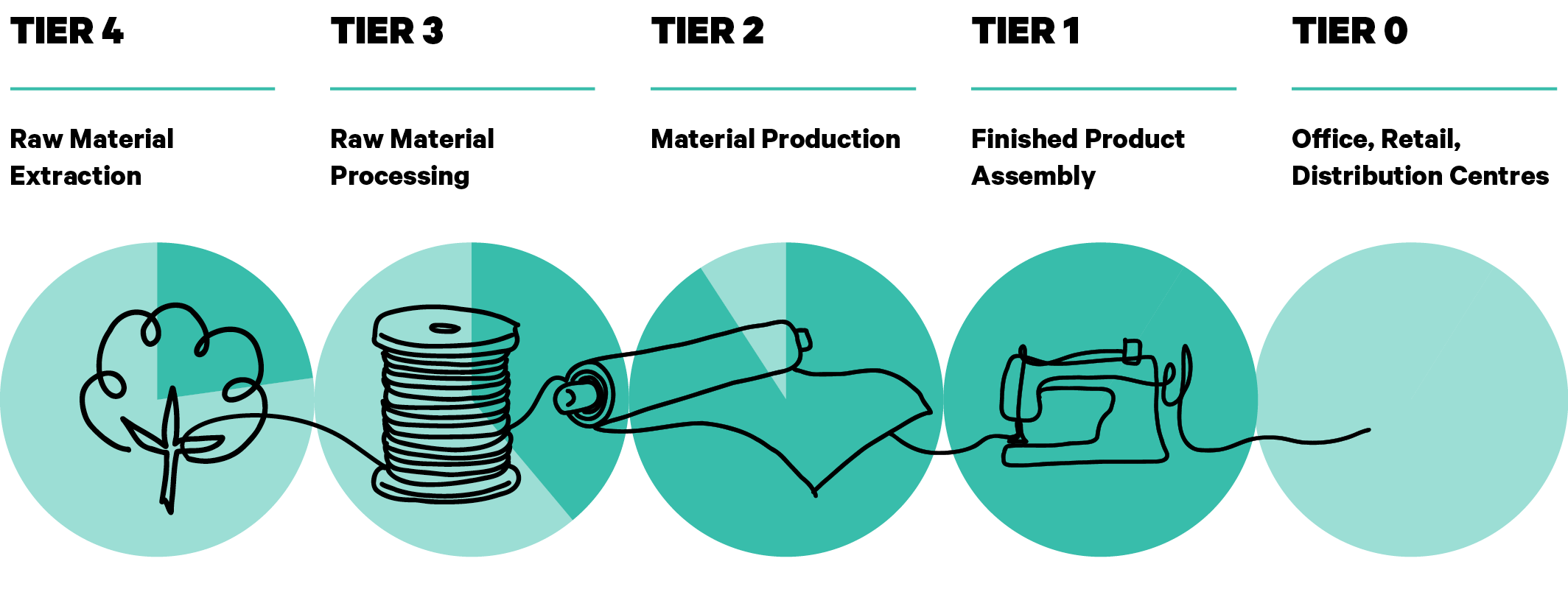

The textile industry’s supply chain is commonly represented in four Tiers, which are used to describe the production process from raw material extraction to the finished product. Tier 4 includes the cultivation and extraction of raw materials from the earth, plants or animals. Tier 3, the processing of raw materials into yarn and other intermediate products. The processing stage, discussed in these articles series, falls into Tier 2 and is often referred to as material production. Tier 1 is the assembly and manufacturing of the final products1.

Tiers 3 and 4 are often cited as the main cause of the fashion industry’s high environmental impact but actually only make up 38% of all greenhouse gas (GHG) emissions in the fashion supply chain. Whilst Tier 2 equates to 53% of the GHG emissions, and requires a significant amount of chemistry and water2.

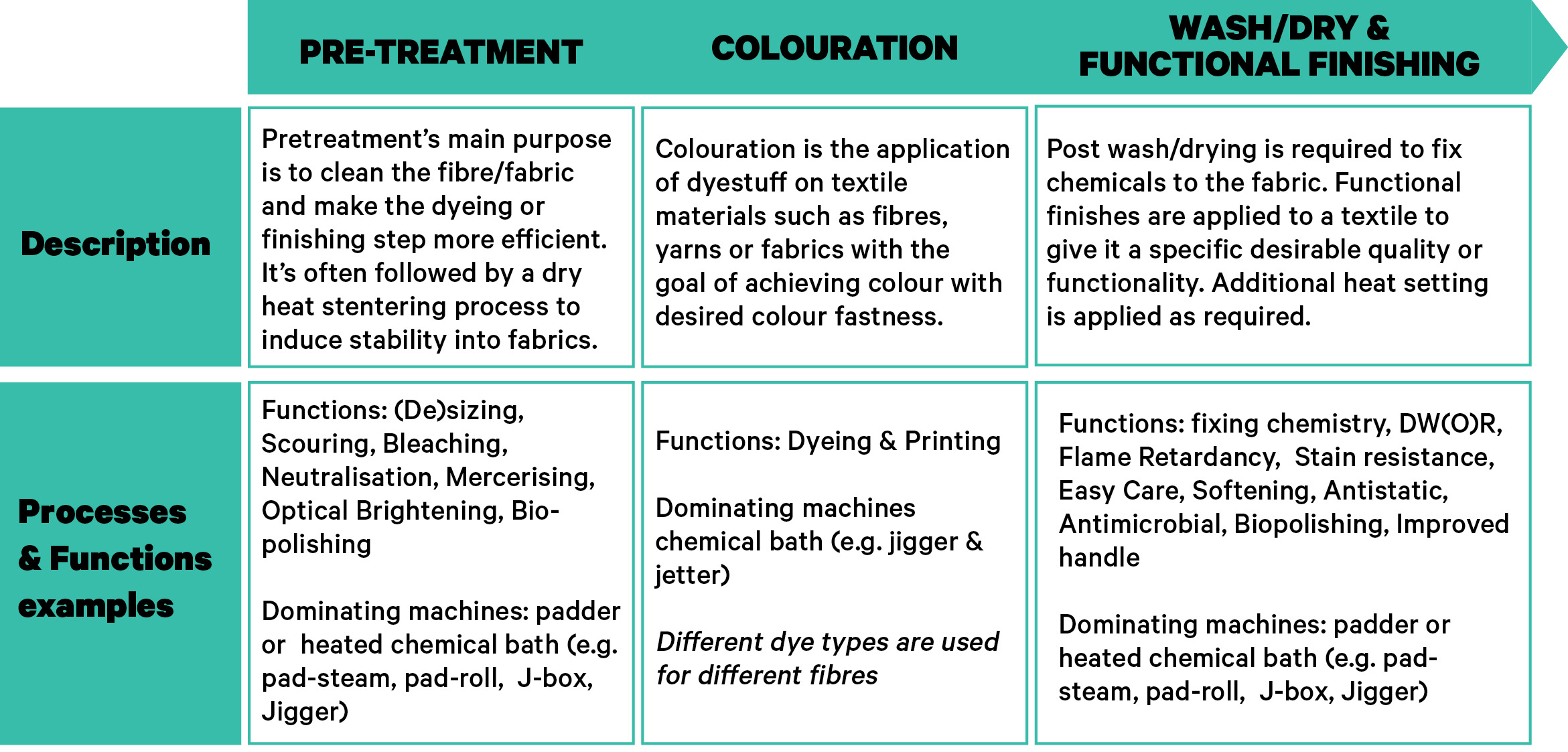

During the processing stage, the fibres, yarns, fabrics or garments go through multiple steps to achieve the performance and aesthetic properties desired by brands and their consumers. These steps can be broadly categorised into pretreatment, colouration and finishing treatments and make up most of the impact taking place in Tier 2.

THE ENVIRONMENTAL IMPACT OF TEXTILE PROCESSING CHEMISTRY AND MACHINERY

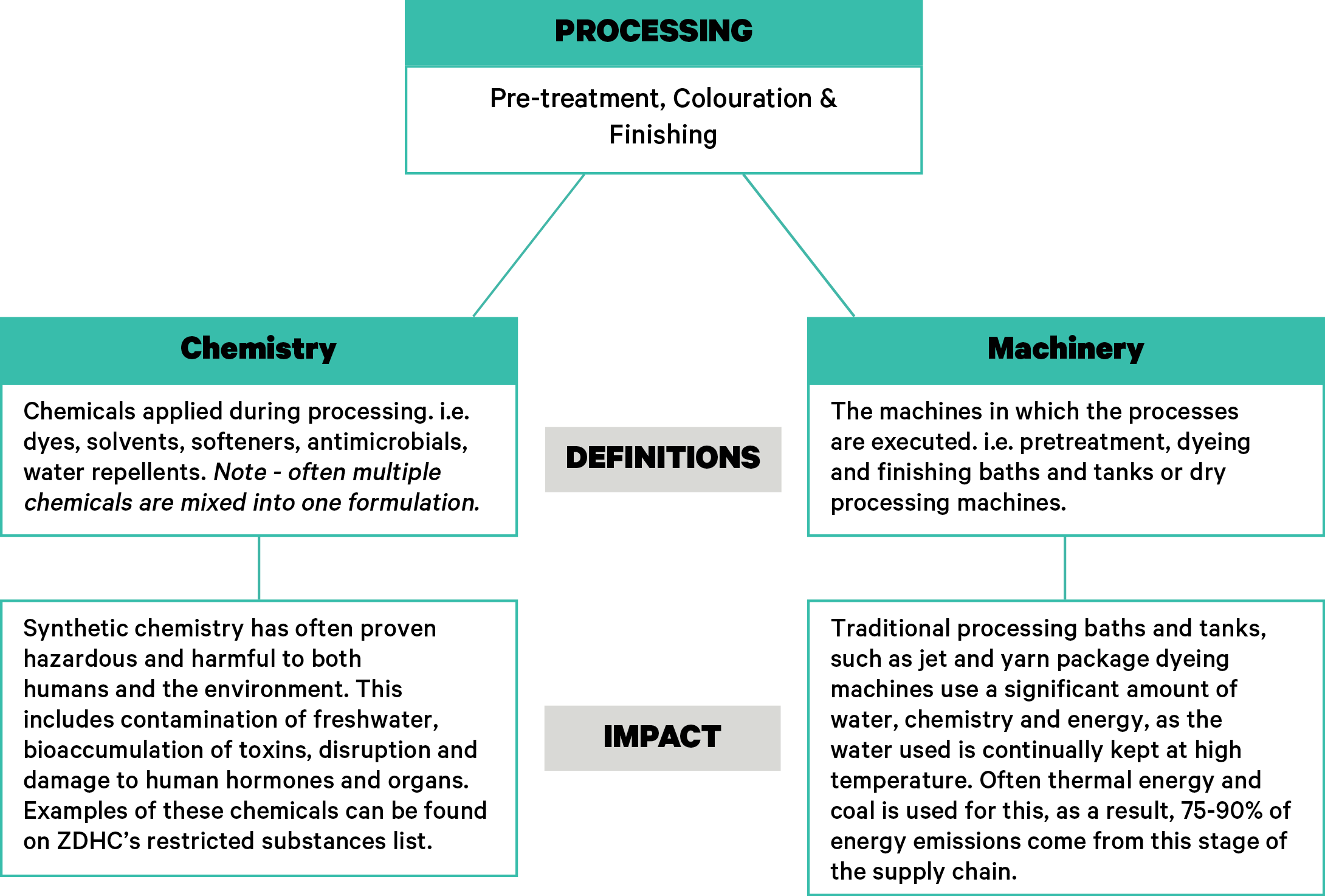

Traditionally pretreatment, colouration and finishing are referred to as wet processes as they take place in large tanks or baths filled with water that is constantly kept at a high temperature3. Alongside the pretreatment, colouration and finishing steps, a significant amount of water and chemistry is wasted as the fabrics also have to be washed off to remove excess dyes and chemicals. Approximately 10-50% of dyes are washed out in this process, ending up in the effluent water4.

Fashion for Good divides the processing stage in two categories to help differentiate between the chemical applied (ie: chemistry) and the process by which this chemistry is applied (ie: machinery).

INNOVATION LEADS THE WAY

A number of solutions exist that can help reduce the use of water, energy and harmful chemistry in this stage of the supply chain. Some of these are incremental solutions5 whilst others are disruptive innovations. As a result, there is ample opportunity to reduce impact in this stage of the supply chain. Fashion for Good works with brands, manufacturers and innovators to orchestrate collaborative projects and pilots aimed at accelerating innovation and implementation. The D(R)YE Factory of the Future, consortium project for example, was launched and orchestrated by Fashion for Good together with partners adidas, Kering, PVH Corp., Arvind Limited, and Welspun India and several innovators in textile pretreatment, colouration and finishing. The project brings together several novel technologies with the aim of disrupting the current processing of textiles in the fashion supply chain.

There’s also the Dyestuff Library, a digital tool enabling partners to choose sustainable dyestuff based on competitive performance and environmental metrics for commercial use. The library, which will accelerate the shift from harmful chemistry to more sustainable options by enabling visibility and access to innovations, is supported by Fashion for Good’s corporate partners adidas, Inditex, bonprix and Otto International (members of the Otto group), BESTSELLER, Target, Patagonia, Paradise Textiles, Welspun, and newest partner Shahi Exports, along with other supporting stakeholders.

The fashion supply chain is complex and its environmental impact lofty. Many of the techniques we use today are antiquated, and harmful to people and the environment. Withal, there’s also a myriad of opportunities for brands, suppliers, and manufacturers to invest in innovations that can disrupt the current supply chain, and thus mitigate the harm caused by the fashion industry.

1 Aii (2023). Taking Stock of Progress Against the Roadmap to Net Zero. Available at: https://apparelimpact.org/wp-content/uploads/2023/06/Aii_RoadmapReport-615-1.pdf

2 Idem

3 Except for printing

4 IntechOpen Textile Dyes: Dyeing Process and Environmental Impact

5 You can learn more about these solutions in Fashion for Good x Apparel Impact Institute (Aii)’s report ‘Unlocking the Trillion – Dollar Fashion Decarbonisation Industry’. The report charts a trajectory for the industry to meet its netzero ambition, breaking down the funding needed and mapping the integral levers across existing and innovative solutions.

Other Articles

In conversation with Smartex: Explore Smartex’s AI-driven solutions transforming quality control and reducing waste

Fashion for Good and Textile Exchange Team Up to Trace Textile Waste