How Can We Make ‘Leather’ Alternatives With Green Waste?

In Conversation with Biophilica: The Innovator Revolutionising the ‘Leather’ Alternative Industry

Mira Nameth, Founder and CEO at Biophilica. Image by Biophilica.

March 2024

Can you please introduce yourself?

I’m Mira, Founder and CEO at Biophilica. My background doesn’t precisely align with the material science or engineering aspects here at Biophilica. I am, first and foremost, a designer. Previously, I’ve worked as an art and creative director with fashion brands in both New York and London. I do have quite a lot of experience with fashion brands, but in a different way than how we’re engaging with them now at Biophilica. Currently, we’re stronger on the supply chain, working with a team specialising in material science, engineering, and scaling.

How did your sustainable journey start and how did that lead to creating Biophilica?

It all started with the birth of my daughter, Nora, in 2013. As I spent time with her, I started thinking a lot about the challenges that we all face, including those she might encounter in her life or that her children might face in the future. I felt a genuine concern, that made me think about my contribution to the world and my desire to be part of some kind of solution. At that time, I had no clear idea of what kind of solution I could offer, and I found myself asking, “What can I do? I’m not a scientist.” However, I knew I was interested in sustainability and I chose to go back to college to do a second master’s degree in Product Design at the Royal College of Art in London.

Exploring various facets of sustainability, I became particularly interested in materials and began investigating underutilised waste streams that were readily available, even in urban environments. That’s when I became interested in green waste, encompassing items like autumn leaves or any leaves and stems originating from trees or bushes in urban settings. This marked the starting point of everything.

Without a clear intention to create a leather alternative, I began working on different samples — foams, rigid materials, flexible materials — that eventually became the embryonic stage of what is now known as Treekind®. Biophilica was founded in 2019, primarily to provide a home for Treekind®. From there, everything has naturally evolved and progressed.

What is Treekind®?

Treekind® is the material we have trademarked. It is 100% bio-based, with no synthetic additives. It is a home compostable material, derived from either green waste, as previously mentioned, or agricultural waste feedstocks. We specifically avoid using anything edible, as addressing food scarcity is a significant aspect of combating climate change. Therefore, our material is crafted from non-edible, raw materials, including agricultural feedstocks sourced from the Midlands in the UK.

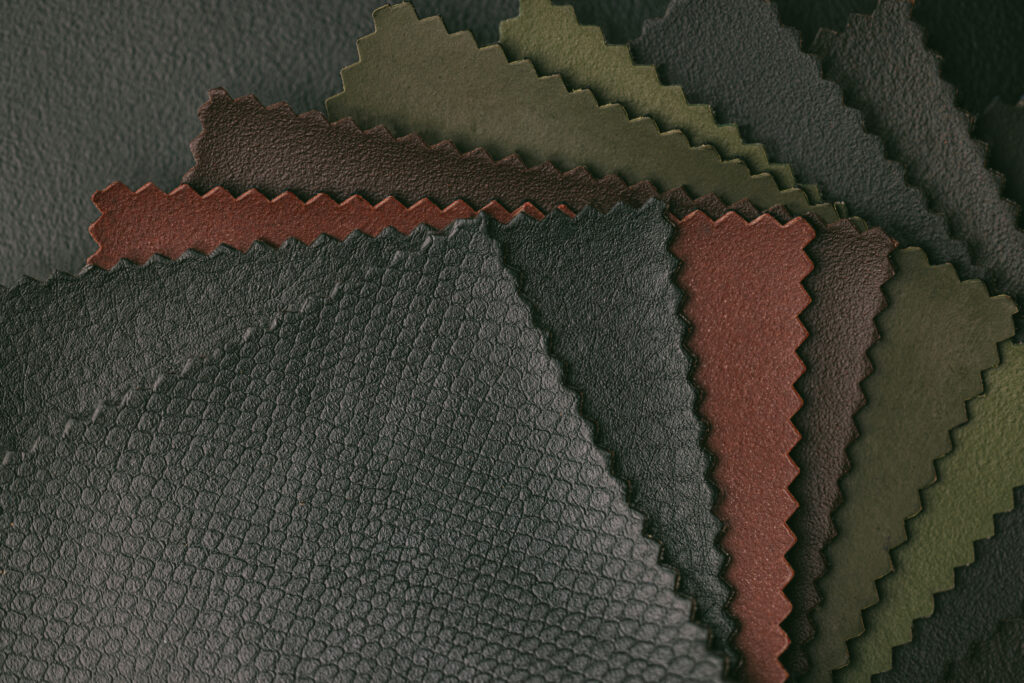

Image by Biophilica.

So in the early days, were you personally out sweeping and collecting bags of leaves yourself? And at what point were you able to outsource that?

I was the slightly eccentric lady walking around Hyde Park and other parks with a small bag, collecting leaves. Wearing stylish clothes while doing so added an element of intrigue, as people would often wonder, “What is she doing? This is unusual and interesting.”

I transformed my kitchen into a home lab, much to the excitement of my husband and daughter. That’s truly how it all began, and I find this approach quite interesting. Creating your material in your own kitchen, with children present, provides insights into the safety parameters necessary for the material. Perhaps all materials should initially be developed like that, as it’s a way to ensure non-toxic materials that are entirely safe.

We talked a little bit about Treekind® and what it’s made of, but what’s this new material looking to replace? What problem is the fashion industry facing and how is your innovation solving that problem?

If you look at animal leather, we genuinely appreciate its beauty. However, there are evident concerns regarding the origin of this material, along with the associated carbon and water footprints in its production. The Global Fashion Agenda in Denmark conducted a survey on various textiles, revealing that animal leather is among the most problematic. Therefore, we have developed Treekind® as an alternative to animal leather, as well as PVC and polyurethane leathers sourced from petrochemicals. We firmly believe that the future materials must be low-resource, with the lowest possible carbon and water footprints, causing no plastic pollution, all while maintaining the durability of natural leather.

In terms of the environmental impact, how have you been able to quantify the impact of your material?

We have done a preliminary Life Cycle Assessment (LCA) of our material, showing really promising results across various parameters, especially the carbon footprint. Our estimated carbon footprint is around 2 kilos of CO2 per kilo of Treekind®, which is extremely low compared to leathers, ranging from 20 to 100 kilos of CO2 per kilo of animal leather. Additionally, when considering water footprints, it’s a fraction, measuring less than 0.1% of the water used in conventional leather production. This significant reduction is attributed to the traditional tanning process for animal leathers, whereas we incorporate pigments into our slurry from the beginning. Consequently, we don’t need to dye or tan our material separately as the pigments are already integrated.

It’s interesting that you mentioned the desire to replace leather alternatives. In our work within the biomaterial space, one key pillar is exploring replacements for leather. We examine various feedstocks, as you mentioned, such as agricultural and garden waste, and explore different processing methods. When dealing with biomaterials, a significant aspect is considering the end products and their life cycle. You mentioned the compostability of your material, and for us, it’s crucial to validate such claims, a task that Biophilica has successfully accomplished. Considering factors like feedstock, processing, the final product, and end-of-life considerations is essential. In the leather alternative realm, we often observe the blending of materials with synthetics to meet brand performance requirements. It would be great to hear more about how you’ve maintained your material as 100% bio, without divulging any proprietary secrets, but shedding light on how you’ve overcome the usual reliance on synthetic elements.

This is one of the aspects we’re most proud of at Biophilica. We’ve successfully created Treekind® to meet performance standards without resorting to coating our material with polyurethane. It’s been a challenging and long process. A key focus has been on the structure of our material, allowing us to surpass demanding tests, such as 150 wet vest rub cycles, a high standard for luxury watch straps, without the need for plastic polyurethane coating. We’ve also achieved success in producing a variety of colours, including challenging ones like white and blue. While we can already make green, red, brown, black, and various other colours, cracking blue and white was a particularly significant achievement for us.

Regarding performance, we meet standards for tensile testing, obtaining results ranging from 12 to 18 newtons per square millimetre, based on our material’s combination. Exploring alternative technologies beyond polyurethane has allowed us to meet water resistance requirements, vessel testing, and various surface and strength criteria.

By thinking beyond the polyurethane box, we’ve discovered numerous possibilities for our material. Recently, we achieved a breakthrough in flex performance by developing a 100 percent bio-based glue tailored to our specific performance and sustainability criteria. This glue, combined with Treekind®, has demonstrated a flex performance of 250,000 cycles, making it suitable for footwear. This accomplishment is incredible, considering our commitment to avoiding any synthetic components in our material.

Image by Biophilica.

An amazing achievement, especially in successfully addressing the intricate components of the material. This is where challenges often arise in the innovation space. As you mentioned, cracking various parameters is crucial, and at Fashion for Good, we recognize that for solutions to scale, they must match or surpass existing technology and performance standards, as well as outperform them in terms of environmental impact – both of which you’ve aptly demonstrated. The toughest challenge lies in the pricing aspect, showcasing the long-term competitiveness of your material compared to what it aims to replace. In the fashion industry, meeting these three pillars is vital for the success of innovations.

To expand on that, you mentioned the fashion sector, but could you elaborate on the industries you have primarily worked in so far? Additionally, what are your key collaborations at the moment?

Our very first collaboration is with a really exciting Swiss watch brand that makes luxury watches, which is called ID Geneve Watches. They’ve garnered significant attention, including investment from Leonardo DiCaprio, marking a phenomenal milestone. Our collaboration has been ongoing, and we’ve specifically tailored our material to meet the requirements of luxury watch straps. This collaboration has resulted in our first product on the market in partnership with ID Geneve.

We’ve been fortunate to collaborate with Fashion for Good and its outstanding team. Working with several Fashion for Good brands, including BESTSELLER, began with sharing smaller samples and has since evolved to the point where we’ve provided material produced on our demo line through a continuous casting process. These brands have not only created prototypes but are also developing new ones using the shared material. We are currently entering the third phase of collaboration with these Fashion for Good brands, spanning across both leather goods and footwear — two market areas well-suited for Treekind®. Additionally, we’ve had the opportunity to work with an auto brand.

We welcomed you into our Innovation Programme in 2021 and a significant aspect of Fashion for Good’s mission is to bring together the different stakeholders in the supply chain – innovators like yourselves, manufacturers, brands, and investors. The goal is to foster collaboration, overcome challenges or roadblocks faced by innovators, and accelerate their implementation into the supply chain. As you mentioned, we’ve been actively engaged in a collaborative pilot with you, where we’ve brought together various players and assisted in structuring the agreement and project parameters. This ongoing project started in 2022 and is progressing well. And as you said, we are now entering the next phase, which is incredibly exciting to witness.

In 2022, Fashion for Good invested in your seed round. Can you elaborate on what role Fashion for Good, as one of your investors, has played in your journey so far?

We owe Fashion for Good a lot. Everything you have done for us has been truly remarkable. We deeply appreciate the pivotal role Fashion for Good has played, not only in investing in Biophilica, as you mentioned, but also in connecting us with our main investor, Rhapsody in Boston. Moreover, you’ve opened up numerous investor conversations for us. Fashion for Good has an incredible network of investors and brands, and this is where your second noteworthy contribution lies. You’ve not only helped establish a platform for us and other innovators to connect with brands and initiate partnerships but have gone further by managing these projects. This includes delving into the legal and project management aspects, driving everything forward from inception to the point where our material is commercialised for large international brands. We couldn’t be more thankful to Fashion for Good.

We’ve enjoyed working with you and appreciate the journey that we’ve had so far. Our significant focus is on transitioning from pilot to implementation, and that’s the ongoing journey we’re navigating together. How do we activate and accelerate those piloting iterations that you talked about earlier? What is essential for you to scale and what’s your primary focus for the coming year?

No big surprise, money. We’re actively fundraising at the moment. The key factor in bringing down the price point of any material is scaling. As you mentioned earlier, one of the critical pillars for a new material is its price point. If you look at the materials we’re competing against, they are already extensively scaled. Consequently, Treekind®, our material, will become more cost-effective as it scales up to mass production — that’s a fundamental reality. Additionally, we’re excited about our 100% bio-based adhesive, which we can produce in significant quantities even at our current facility. We are on the brink of scaling that material soon. However, for Treekind®, the scaling process is more intricate. We are exploring collaborations with external continuous lines to expedite the process, avoiding the necessity of setting up a complete, large-scale factory. This strategy aims to quickly bring our material to the brands we’re collaborating with, including Fashion for Good.

Image by Biophilica.

What we observe is that hard tech innovators, like yourselves who are producing something, require significant investment to scale production and meet the industry’s demand. It’s intriguing that you’re considering leveraging existing infrastructure or forming partnerships. At Fashion for Good, a substantial part of our work involves assisting companies, such as Biophilica, in identifying the most suitable production and revenue models for different stages of their scaling journey. It’s about determining when building your facility makes sense and when partnering with someone is the optimal choice. I’m genuinely excited to collaborate with you on these next stages. In conclusion, you should take immense pride in everything you’ve achieved and what your company has accomplished — it’s truly impressive. For those interested, where can they find and purchase Biophilica products?

Right now, we strongly recommend visiting the ID Geneve Watches website to explore everything they showcase and have available for sale. You have the option to select a Treekind® watch strap. Hopefully, in the near future, working collaboratively with our Fashion for Good brands, we can introduce smaller collections of Treekind® products to the market. We’re aware of the considerable consumer interest as we receive weekly inquiries about where to purchase our products. We are excited about this existing enthusiasm and interest, and our goal is to collaborate with the brands we have partnerships with to make Treekind® accessible to a broader audience in the mainstream.

Accessibility is crucial. Sustainable materials must not be limited to a small group of consumers. This is a significant aspect for us at Fashion for Good, and it’s why we collaborate with a diverse range of brands and manufacturing partners. We recognize the importance of having both large and small entities on board for the journey, as each plays a vital role in driving change. Shifting away from the business lens, my final question to you is as a sustainability professional: what advice would you offer to consumers aspiring to live a more sustainable lifestyle?

I think one of the key things is to do a little bit of a deep dive into what people say and what they can actually verify. As you mentioned before, we’ve conducted composting testing as an ISO test. So, this is something that we assert and that we can verify. Customers need to scrutinise greenwashing and truly understand the certifications associated with different materials and products.

The other aspect is to put your money where your mouth is, essentially. Be the change that you want to see. Choosing what you decide to purchase is a strong way to influence how the world operates. As a consumer, you hold purchasing power. So, if you want to see the change, show that change with your purchases.

Video Interview

Other Articles

In conversation with Smartex: Explore Smartex’s AI-driven solutions transforming quality control and reducing waste

Fashion for Good and Textile Exchange Team Up to Trace Textile Waste