In Conversation with Circ: The Innovator Turning Textile Waste into New Materials

Luke Henning, Chief Business Officer of Circ. Image by Circ.

20 October 2023

Can you tell us about Circ, how it started and what the organisation does?

Circ is a recycler of blended textiles, focused on polycotton. We originally started in a different industry: the biofuels green chemical space. The extraction technology we developed to pull the chemicals out of the plants was adapted later on for use in textiles. Essentially, we shifted into textiles at the end of 2017, after we tested and we found out that we could do it. We tried to understand if people were interested in the space and we looked for alternative applications because the technology we built did not have a very good fit in the market. We did a whole lot of googling and searching on the internet and we came across C&A Foundation, which is now Laudes Foundation. We reached out to them on LinkedIn and they introduced us to Fashion for Good, which they had recently supported and started. Fashion for Good, then, shared a lot of information with us, came and investigated our technology, and we joined the Scaling Programme as one of the first innovators. Fashion for Good introduced us to all the brands and started taking us to conferences, and from that moment we immediately felt the market pull. That’s when we transitioned the entire company to textile-to-textile recycling, and that’s what we’ve been doing since. We had a Series A investment, which was led by Patagonia through their Tin Shed Ventures, we brought in some more textile-focused people and we scaled from doing one t-shirt at a time to now, where we can do very large runs. We then had a Series B investment, which was led by Breakthrough Energy Ventures with participation from Inditex and Zalando. Recently, we’ve also released a collection with Zara.

Image by Circ.

What problem is your innovation solving? Why is this innovation needed?

The problem we’re solving is blended textiles. The challenge is that as soon as you get to blends, there’s no one who’s really able to take the blends apart and use both pieces of polycotton back into the textile supply chain. For example, referencing the Zara collaboration, that was the first time we could showcase an actual sellable product where someone had taken polycotton, separated the polyester from the cotton, used the polyester to make new polyester and used the cotton to make lyocell. Both polyester and lyocell were not only viable as textile fibres but also great, high-quality fibres. There are people recycling polyester and there are people recycling cotton, but there’s no one really able to tackle the blends and take them both back into the textile supply chain, especially if you get to the fact that we deal with mixed ratios. We, at Circ, could take both multiple ratios and mixed colours.

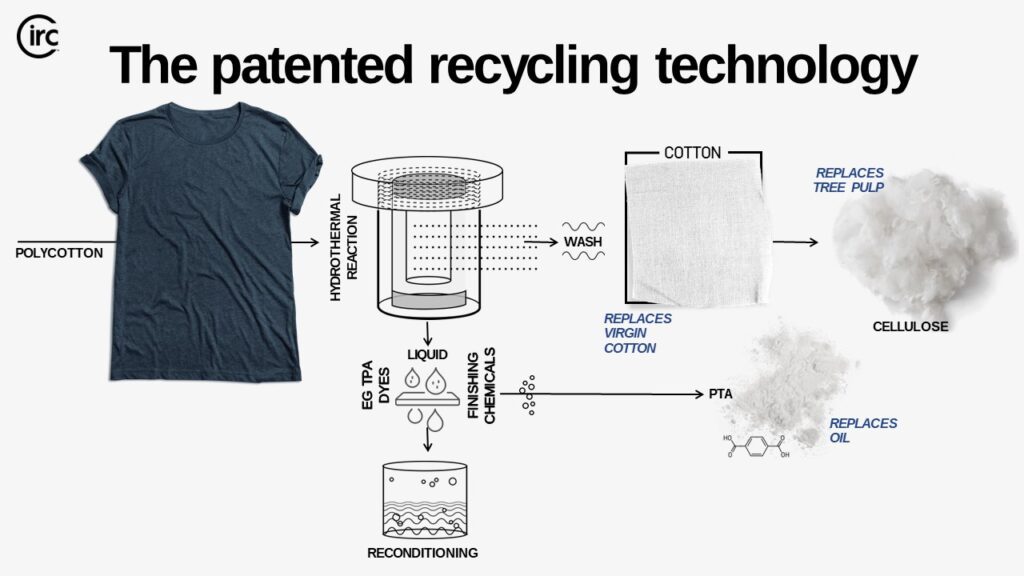

Can you explain how Circ hydrothermal technology works?

We are depolymerising the polyester. Polyester is a whole lot of molecules that have been put together. What we’re doing is we’re breaking them apart, almost like we’re chopping the pieces apart, to get back to the original building blocks. Then, the polyester breaks down and goes into the liquid. And we extract those chemicals, those basic building blocks, from the liquid, we purify them and after that, we’re able to recombine them to make new polyester. So that would be through a normal polymerisation process and once it’s in that pellet form, it can go through the normal supply chain. We do this process in a gentle enough way that we don’t completely destroy the cotton. The cellulose in the cotton is a very pure form of cellulose, and instead of using trees to make the man-made cellulosic, we take that down a cellulosic route and we’ve tailored our cellulose to be suitable for making lyocell specifically. We focus on lyocell because we see it as a more sustainable alternative to viscose. In short: the polyester is broken down to its building blocks and rebuilt into new polyester. The cotton is broken down into its basic cellulose, so it can be rebuilt as lyocell.

High-level process overview of Circ’s patented poly-cotton recycling process. Image by Circ.

What have been the biggest challenges so far in Circ’s journey to scale?

I think one of the challenges is how the fashion and textile industry deals with innovation and where it is in the recycling journey, as I think they’re quite a bit further behind when compared to packaging. We’ve seen this huge shift over the last three to five years, where people have become aware of textile recycling, but we’re still in that education mindset and trying to get brands to buy both in terms of direct financial support and in terms of capital, but also in terms of supporting through things like offtake. There are a lot of brands’ commitments that have been made, but there’s a lack of distinct action from many of the brands, in terms of putting real money at risk and providing offtake for the innovators. If you’re not going to invest in R&D, you can’t really expect it to happen.

What have been the biggest successes so far?

One specific milestone we were able to achieve is that we were able to take our process from batch to continuous. And that’s important because if you’re going for a scaled chemical process to the extent that you can get into a continuous process, it means that you can reduce both the cost of the facility, the size of the facility and the operating costs of that facility. I think as well, there have been some really nice innovations that we’ve developed, during our process, to help make it more sustainable. Another of our biggest successes, I would say, has actually been building an amazing team of people who are passionate and come to work giving their best, because they really want to make a difference in the world. We have an incredible team. On the partnership side, we’ve been very strategic in how we’ve put together partnerships and that’s been a real success for us. And then, getting to that point where we’ve been able to showcase something real in the market, it’s a huge success. I think there have been a lot of successes over the years, but those are just some of the key highlights.

Circ Cellulose Steps. Image by Circ.

What are the biggest hurdles the industry has yet to overcome? And what changes would you like to see in the coming years?

I think supply chain adoption is going to be challenging in a lot of ways. The supply chain has been forced over time to operate incredibly efficiently but with razor-thin margins. So getting your supply chain partners and finding ones that are willing to transition and to try out new materials and prove that they actually work like virgin materials, takes time and it’s a bit of a challenge. I think there’s a lot of appetite for sustainable and fashion investing, but those are both relatively new areas. And I see the general market uncertainty that’s happening at the moment, meaning that the time it takes to raise the money you need to build full-scale facilities is taking longer. So I think fundraising for full-scale facilities and supply chain adoption are going to be challenges. And then getting these large corporations to move fast is another challenge.

What role does collaboration play in bringing innovations to scale?

We’re tackling such a large issue that my competitors are very much collaborators. We work very closely together to try and build this industry as a whole. Even if all of us were to operate with our facilities, by 2030 we still would not be bumping elbows, because we’re dealing with a big problem. I see a huge space for collaboration in this industry among my direct peers, but also you need all the supporting technologies in sorting, grading and collection to be developed at the same time. If we want to be able to tackle post-consumer, there’s a lot of supporting technology that will need to be built, and that’s where a lot of collaboration will also happen. So it’s both horizontally and vertically that you need this collaboration.

What’s next for Circ? (in terms of business growth & product development)

We are putting together all the materials we need to support the fundraising for a first full-scale facility. All of the engineering is happening in parallel and we’re looking to sign all of those offtake agreements to secure supply contracts, finalise the location, and nail down all of the governmental and regional support that we need. We’re having conversations with banks already and we’re increasing those now. It all comes together to allow us to build a full-scale facility and prove that it can operate profitably with decent margins.

Image by Circ.

How has Fashion for Good played a role in your journey so far?

Fashion for Good has always been a really strong supporter of ours. And, actually, they were the people who hold our hands and helped us move along this journey from the very beginning. None of us, who did the transition from Tyton Biosciences to the textile industry and to textile recycling, came from a fashion or textile background. So having a partner who could hold our hands, share industry knowledge, share industry experience, and share industry access with us, was incredibly helpful. Fashion for Good took us to conferences so we could get exposure, they had direct brand meetings for us, especially in the beginning, we collaborated on pilot trials, they supported us whenever we made announcements, and they are a small investor in us.

Lastly, what advice would you give to consumers trying to be more sustainable?

It’s very difficult to go from a low base to fully waste-free, circular or sustainable. I would say to people: understand your impact a bit more and think about ways every day that you can improve and move along this journey because it’s a journey. If all of us just took stock of what we do and tried in little ways, every day, to be more sustainable, that’s how you get there. Because it’s difficult to make huge changes or to change things from one day to the next. What you want is to actually build towards that, because it’s a lifestyle change. We don’t realise how much we have been trained to consume in a single-use mindset and in a single-use way. And so making the transition to being more waste conscious, takes time and effort. When it comes to the textile and fashion space, buy less, buy higher quality, look after your clothes so you keep them in circulation as long as possible, and repair as much as possible so they stay in life as long as possible. Then, when you have to dispose of it, I would, if it’s still usable, dispose of it to a second-hand market. If it’s not, I hate to say it, at this point, it’s just going to waste. In the future, there will be systems to recycle those, but it’s not being recycled now. The other thing I would say to consumers is don’t become overwhelmed. Do what you can do, because every little thing helps.

Other Articles

In conversation with Smartex: Explore Smartex’s AI-driven solutions transforming quality control and reducing waste

Fashion for Good and Textile Exchange Team Up to Trace Textile Waste