In Conversation with Trove: The Innovator Powering the Resale Ecosystem For Brands

Founder and Executive Chairman of Trove

Andy Ruben, Founder and Executive Chairman of Trove. Image by Trove.

12 September 2023

Can you tell us about Trove, how it started and what the organisation does?

Trove originally started in 2012 as a peer-to-peer marketplace. In 2016, we started focusing on brands. In 2017, Patagonia became our first brand partner, followed by Eileen Fisher and REI that same year. Nevertheless, the idea and the mission have always been the same. Our vision stems from the idea that the best supply chain is no supply chain at all, and that the most efficient way of making something is by using something that already exists. As the trend of thrifting, resale, pre-owned and pre-loved has grown, there has been a customer shift. And, as that shift takes place, brands who have made these items in the first place have a lot at stake: they have a lot to lose and they have a lot to gain. Trove powers those brands to follow their items past the initial sale, to continue to monetise the items that they have designed, made and sold for the first time. We do that with logistics, with technology, with program expertise and design. Today, we work with some of the leading brands in the world.

What problem is your innovation solving? Why is this innovation needed?

The challenge for brands is that if you’re Patagonia and you’ve made a ‘Nano Puff’ and you sell the item the first time, that item might be sold two or three more times on eBay or on a different marketplaces. In a way this is a risk for Patagonia to lose the opportunity to own their brand, monetise that item and stay close to the customer. And on the other side, it is also an opportunity, for a brand like Patagonia, to continue to follow that item and to view that first sale not anymore as the end of the journey, but as the starting point. This process requires a technology that doesn’t exist today for brands and the ability to track every individual item and know the condition of each piece that comes back in, how to list that item, where to sell it, how to describe it, how to price it and how to merchandise it. Brands don’t have this technology yet, but Trove allows them to rent it, so they can take part in this massive growing resale space.

Can you explain how the Trove recommerce platform works?

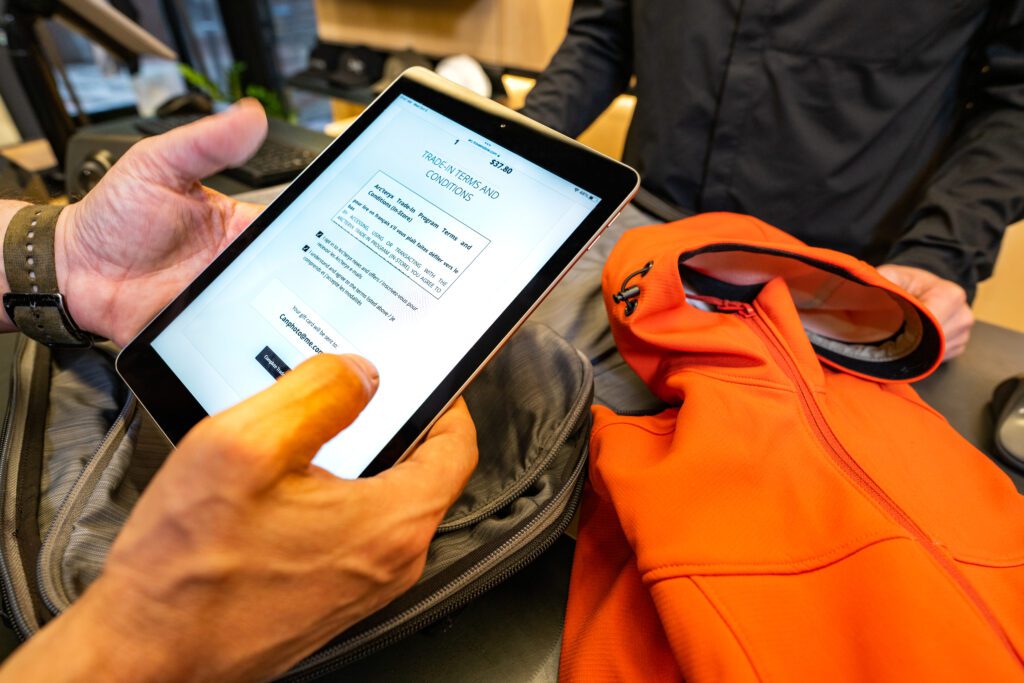

Trove technology has four different steps. Starting with the first step, if you bring, for example, an Arc’teryx piece back to any store, there’s an employee in that store that will use Trove technology to identify the price and give you a gift card for the piece you’ve just brought back. The first step of the technology is the trade-in technology.

The second step is what happens to that jacket afterwards. That jacket could go to an Arc’teryx facility or a Trove facility, but there’s technology in that facility to condition grade, merchandise, list and add the attributes to that item, so that Arc’teryx can get the most amount of value for it. That might include Arc’teryx selling the item itself, or it might include Arc’teryx deciding to sell that item on a marketplace, or if it’s not in sellable condition, it could be upcycled, recycled, etc. That’s reverse logistics technology.

The third step is the ability to sell that item. You can imagine Arc’teryx having 100 thousand different items: how do you merchandise those items on a website? The technology that Trove has built and Arc’teryx can then use, allows them to merchandise that jacket in the scope of an online storefront. Or, if they chose, in a capsule in a physical store where you might have brought the jacket back in.

The final stage of the technology is just the end-to-end data picture, the insights: when was that item originally made? How has it now come back? How many times has it come back? What is the overall price we paid to bring it back compared to the price we resold that item at? This step includes the insights around customers, the brand and the finances, that allow brands to build this as a business.

Image by Trove.

What have been the biggest challenges so far in Trove’s journey to scale?

The biggest challenge in this space is that there’s a lot of interest, but it’s still a sub-scale. Even the players who are the furthest advanced, they’re still operating at a small percentage of the mainline business. It’s difficult for any player in this space to have enough funding, money and profit upfront to invest in new technologies to serve these world class brands. Undoubtedly, at some point over the next few years, 1 in 4 items will come from somebody else, instead of from a new supply chain. Brands understand that this transition is coming and they wanna be prepared for it, but it’s not here yet. I think one of the greatest challenges is to understand how to design a system that’s right for brands to build long-term businesses, and furthermore integrate this system into e-commerce, stores and wholesale. Building this technology ahead of the market has been one of the biggest challenges.

What have been the biggest successes so far?

The part that I enjoyed the most is working with leading brands. We’ve just launched a program with Carhartt and Canada Goose, and when we work with these brands, we get inspired by their history, their narrative, what they stand for, and by their abilities to take single items and make those items theirs. I think the biggest wins have been staying true to the vision that the brands that we love and respect will do this as part of their values. If we as customers identify with a brand and that brand makes it easy for us to buy pre-owned items that we can always bring back, this allows more items to stay in use longer and therefore reduce the footprint or the linearity of the model we have now.

What is one lesson you’d pass on to other entrepreneurs working in this industry?

If I look back, there have definitely been moments that we’ve seen the writing on the wall for something and it’s always easy to say we’ll do it soon, but not now. I think the key is really staying close to your customers, that for us are our brands, and understanding what things make sense to do now and not to wait for, and ask yourself if that’s the right investment, for example, and if it fits with the long term perspective of where the world is going. And to make those decisions as quickly as possible.

What are the biggest hurdles the industry has yet to overcome?

I think that the legislation in the EU is laudable and exciting. The directives that are happening in the EU compared to the US are great. What I don’t see yet, that I remain very concerned about, is that we’ll need that regulation because we’re dealing with individual actors that have different incentives compared to the overall system. And, even though I believe the brands in the fashion industry to be well-meaning and really wanting to be doing the right thing, the incentive structure that surrounds them is focused on growth. No matter how less bad or smaller the footprint is for every blouse or every pair of pants, the fact that we made 150 billion garments in the last 12 months, dwarfs everything else. It’s very difficult for an individual brand to address the growth in the overall industry. I think that there have to be more hard facts in the actual unit growth that provide a mechanism and back individual actors who are intent and want to do the right thing, but exist today in an industry where it’s almost an unfair task.

Image by Trove.

What role does collaboration play in bringing innovations to scale?

I probably have a slightly different viewpoint than many in the space. I feel like I’m doing my job when the brands we support are more competitive and can run a better business than they could before Trove or without Trove, and they clobber anyone they compete with. And as we support more players who do that, their business grows and they grow in a more productive way. Of course there needs to be collaboration on things like standards and collective action, but when we talk about business itself, one of the benefits of business is the competition. And that competition, I think, it’s an incredible force for actually driving the change in these circular models and driving greater innovation.

What’s next for Trove?

We see a vision of 1 out of 4 items coming from other people. And right now at best, if we look at the industry resale for brands, is still less than 1%. Currently, 65 to 75% of all branded resale in the world is going through Trove technology, so I think we’ve a lot of opportunities to accelerate the growth of this industry. The growth we’re focusing right now is about scaling the technology and what’s really taken a long time is making sure the technology’s ready to scale.

How has Fashion for Good played a role in your journey so far?

When I talk about the things that, as an entrepreneur, you have to figure out, one of the most important ones is the connections to see things that you don’t necessarily notice at first. A good example, recently, with Fashion for Good is that we’ve spent multiple calls with European regulation. And that is something that we are not experts in, but the ability to get up to speed with a partnership, with Fashion for Good, has been extraordinary for us. I don’t know how long that would’ve taken if we were not working with you all. Introductions to brands that we wouldn’t have had exposure to, brands who are showing up with Fashion for Good, who are asking questions, and where Fashion for Good can make the connection to innovators, and whether or not that turns into a commercial partnership it’s all learnings for convening groups of people who are trying to drive a change in a similar direction. Fashion for Good is such a good example of how you bring together like-minded people and share knowledge that benefits everybody so that we can be more competitive.

Lastly, what advice would you give to consumers trying to be more sustainable?

It’s very difficult to understand when a brand is doing something that really aligns with your values and when it’s not, but increasingly more and more customers are doing that. Buying used, buying an item that already exists, hands down, is one of the best things we can do. We think so much about how items are made, which is great, and we need to think more about that. At the same time, the best thing we can do is buying an item that doesn’t need to be made. I would recommend finding an item, whether it’s at a thrift store or on a marketplace, or from a brand that has a buyback and resale program. The goal is to keep items in use. We can all use items forever, it totally works. But most of us don’t do that, most of us crave new things. And so, if we crave new things, we might as well move the things we’ve already made around a lot more. And the easiest and best way to do that is that every brand you shop with just has new and used, side by side, integrated together. And whenever you’re shopping new, you’ve got used options as well.

Video Interview

Other Articles

In conversation with Smartex: Explore Smartex’s AI-driven solutions transforming quality control and reducing waste

Fashion for Good and Textile Exchange Team Up to Trace Textile Waste