From Waste to Black Pigment

Photo by Katrin Hauf for Unsplash

8 February 2022

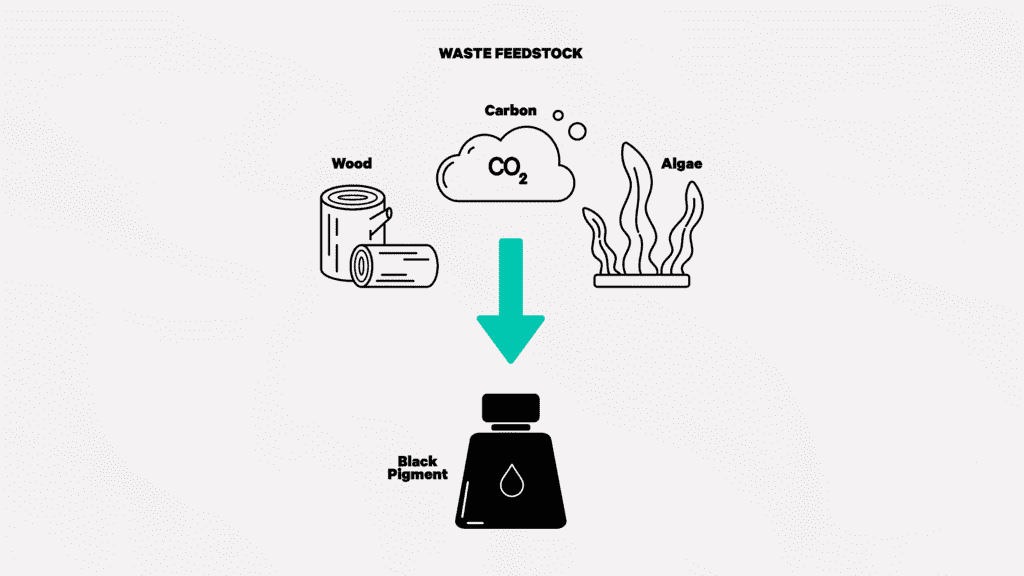

AMSTERDAM – Today, Fashion for Good launches the Black Pigment Pilot project together with partners BESTSELLER, Birla Cellulose, Kering and PVH Corp., in collaboration with Paradise Textiles, and innovators Graviky Labs, Living Ink and Nature Coatings. The pilot aims to validate and scale black pigments derived from waste feedstocks such as industrial carbon, algae and wood that could replace synthetic dyes offering a more sustainable means of textile production with a lower carbon impact.

Fashion for Good Pilot Project Turns Waste Materials to Black Pigments for Dope Dyeing

“Collaboration is key to making a step change in replacing the abundantly used harmful dyes in the industry, of which black is dominating. We are very excited to be able to support this first-of-its-kind collaborative pilot aiming to validate three technologies that will enable the industry to switch to more sustainable (black) dye chemistry.” — Katrin Ley, Managing Director at Fashion for Good

The colour black has a long history in the fashion industry and is one of the most commonly used colours to dye apparel. Modern synthetic dyes are often derived from petro-chemical compounds, which are non renewable and contribute to water pollution when not treated correctly.

The project aims to develop and scale black pigment for the dope dyeing of man-made cellulosics (MMCs) fibres and recycled polyester (rPet) yarns, evaluating the technologies of the participating innovators; Graviky Labs, Nature Coatings and Living Ink, who produce black pigment from industrial carbon emissions, wood waste and waste algae, respectively.

Waste feedstocks used to create black pigment. Image by Fashion for Good

Thus far, their technologies have only been used in printing applications. To develop formulations for dope dyeing, the innovators will be supported by Fashion for Good partner Birla Cellulose and Paradise Textiles, the dedicated material science and innovation hub of the Alpine Group. Birla Cellulose brings technical know-how and insights into the production of dope dyed MMC fibres and Paradise Textiles is known for its consciously crafted collection of sustainable and performance fabrics as well as integrated, advanced manufacturing processes.

The first phase of the pilot will run until mid 2022, with Birla Cellulose and Paradise Textiles producing the first dope dyed MMCs fibres and rPet yarns respectively, using the black pigments. Participating Fashion for Good partners will have the opportunity to evaluate the performance, colour fastness, wearability and impact of all solutions. Successful formulations will then go on to trial larger production runs with fabrics dyed using the innovations.

To assess the performance of dope dyeing with the innovative black pigment formulations, test variables such as affinity, colour and light fastness, and tensile strength of the fibres and yarns, will be measured against dope dyeing with the standard synthetic dyes currently used in the industry. Successes in the initial trials, will be developed towards scaling the project beyond fibre and yarn dyeing to textile production with the long-term goal to integrate these technologies at commercial scale in the value chain.

More information about these pigment innovations, as well as dope dyeing, can be found in Fashion for Good’s Textile Processing Guide.

Other Articles

In conversation with Smartex: Explore Smartex’s AI-driven solutions transforming quality control and reducing waste

Fashion for Good and Textile Exchange Team Up to Trace Textile Waste