Fashion for Good invites SoftWear Automation to its Scaling Programme

Fashion for Good is pleased to announce a new collaboration with SoftWear Automation Inc., an Atlanta-based robotic sewing company. SoftWear and Fashion for Good will work together to encourage the widespread use of fully automated Sewbot™ worklines for t-shirts and apparel, footwear and home goods.

8 August 2017

AMSTERDAM– Fashion for Good, a global initiative to make all fashion good, and SoftWear Automation Inc., the Atlanta-based robotic sewing company, jointly announce today that they will be collaborating through Fashion for Good’s Scaling Programme to facilitate change that is accessible, affordable and attractive for all.

SoftWear and Fashion for Good will work together to encourage the widespread use of fully automated Sewbot™ worklines for t-shirts and apparel, footwear and home goods. This collaboration demonstrates a shared commitment between SoftWear Automation and Fashion for Good to fast-track sustainable innovation within the apparel supply chain.

Other Articles

Steady in the storm: navigating change and growth in 2024

With the end of 2024 approaching, we took some time to reflect on a year marked by both progress and complexity in the pursuit of sustainable innovation. It has been a pivotal year for Fashion for Good, defined by deeper collaborations with brands, suppliers, and investors to accelerate the scaling of innovations. Here are some reflections from our unique point as a global convener and catalyst for change in the fashion industry.

Key findings from the Fast Feet Grinded Collaborative Pilot

Fashion for Good launched the Fast Feet Grinded Collaborative pilot in 2023 with FastfeetGrinded, Target, adidas, Inditex, and Zalando to test and validate the footwear recycling process and support the uptake of recycled materials in footwear.

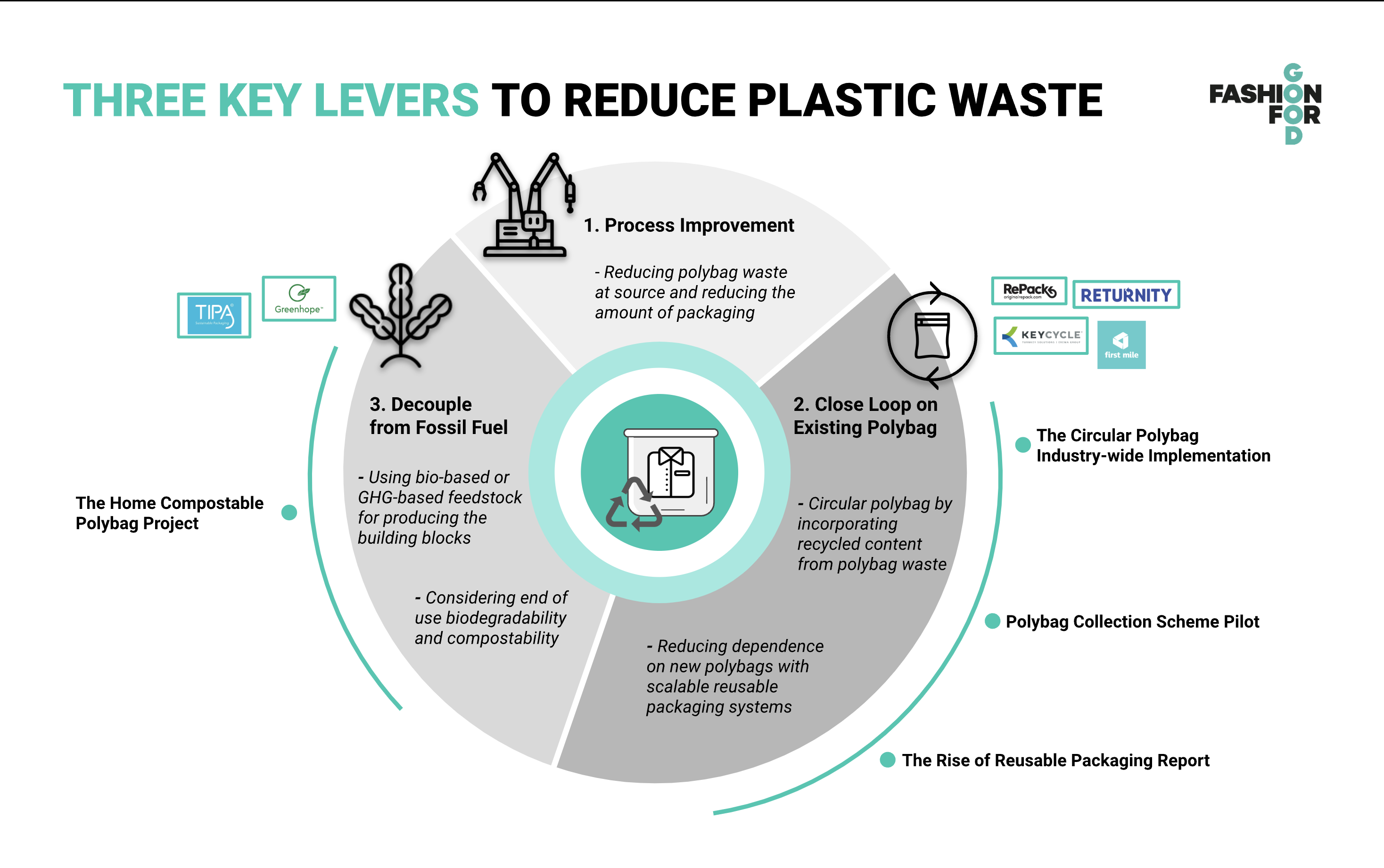

Unpacking the Packaging Problem: Solutions and Strategies

Back in 2019, Fashion for Good dove into the world of packaging and did an extensive exercise of mapping plastic waste flows through the fashion supply chain. Through this work, we identified three key intervention levers: reduce plastic through process innovation, close loop on existing plastics and decouple from fossil fuels. Read below the insight from our five multi-stakeholder reports and projects aimed at addressing two of these three levers.